Airships: Meaning, Difference, Function, Discovery, Design

Jim Goodrich • • Reading time: 34 min

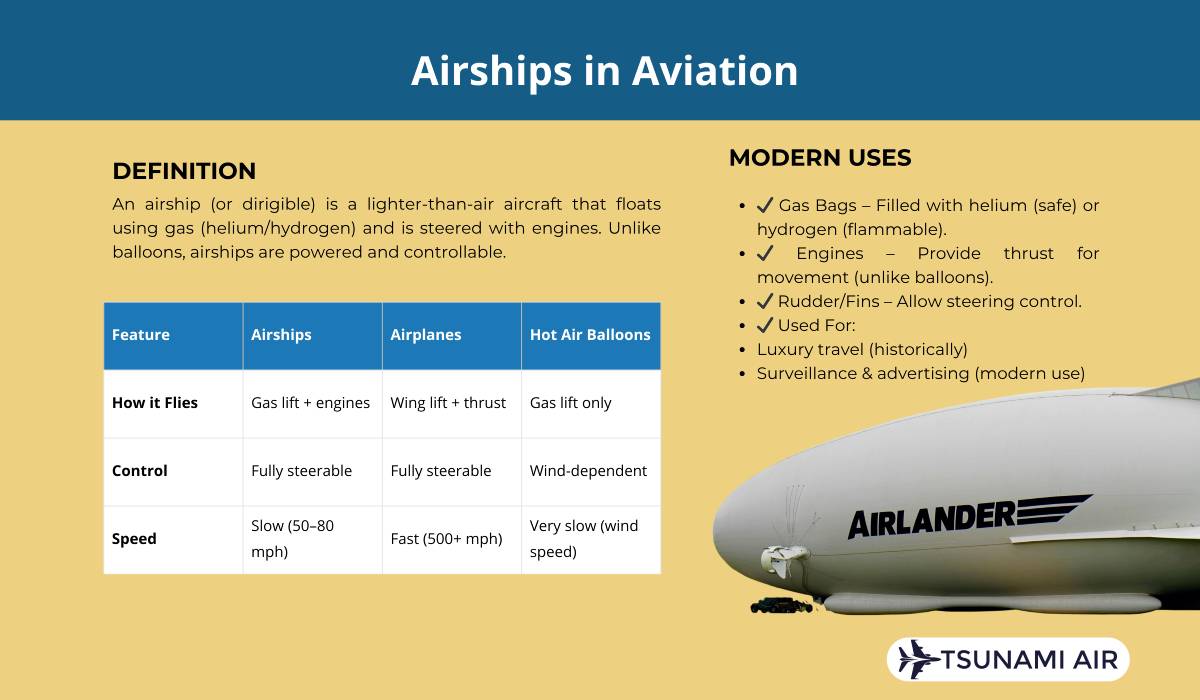

Airships are lighter-than-air aircraft that achieve flight through the use of a large envelope filled with buoyant gas. The design of airships incorporates elements like the hull, structure, and envelope to guarantee stability and functionality during flight. Airships operate at specific altitudes and serve various functions, including cargo transport and passenger travel. Zeppelins and blimps represent two distinct types of airships, each with unique construction and operational characteristics. Understand the history, meaning, and technical aspects of airships to appreciate their function in aviation.

An airship is a type of lighter-than-air aircraft known as a dirigible. It achieves lift through the use of helium or hydrogen contained within a large balloon. Engines drive propellers to create thrust while rudders and elevators provide precise control for steering. Airships maintain structural integrity through rigid, semi-rigid, or non-rigid designs. Non-rigid airships rely solely on internal gas pressure to maintain their shape, while rigid airships feature a durable metal framework aiding multiple internal gasbags. Semi-rigid airships incorporate partial internal support to balance rigidity and flexibility.

The difference between an airship and a blimp lies in structural design. Airships maintain their shape through a rigid or semi-rigid internal framework, while blimps rely entirely on gas pressure to maintain their form. Rigid airships allow heavier payloads to be carried, whereas non-rigid airships depend entirely on helium pressurization and are more suitable for lighter tasks like advertising or surveillance. As of 2022, there are 25 blimps in existence, with half actively used for advertising purposes.

Airships work by combining buoyancy from lift gases, adjusting ballonet pressure for altitude control, and using mechanical systems for propulsion and stability. Helium, with a density of 0.1786 kg/m³ (0.01115 lb/ft³), provides buoyancy based on Archimedes’ principle. Fins and rudders stabilize the airship during flight, while engines generate thrust through propellers. Propulsion system efficiency minimizes energy consumption, and control surfaces counteract yaw and roll movements.

Giffard’s airship utilized a three-horsepower (2.24 kilowatt) steam engine, enabling travel 17 miles (27.35 kilometers) from Paris to Trappes, France, at a speed of five miles per hour (8.05 kilometers per hour). Count Ferdinand von Zeppelin advanced airship technology with rigid airship design, completing the LZ-1 in 1900. The LZ-1 was a 128-meter-long (420-foot-long) vessel powered by two 16-horsepower (12-kilowatt) engines, achieving speeds of 20 miles per hour (32 kilometers per hour) and carrying five passengers.

Modern materials highlight the importance of lightweight and high-strength materials in boosting structural design durability. Propulsion systems achieve fuel efficiency by incorporating technologies specialized to airship aerodynamic efficiency. Control mechanisms guarantee stability and precise handling under varying conditions.

What is the meaning of airship?

An airship is a type of lighter-than-air aircraft, also known as a dirigible, which is filled with buoyant gas and propelled forward by engines for controlled flight. Airships achieve lift through the use of lighter-than-air gases like helium or hydrogen contained within a large balloon. Engines drive propellers to create thrust, enabling forward movement. Rudders and elevators provide precise control for steering and adjusting pitch during flight. Non-rigid airships, known as blimps, rely solely on internal gas pressure to maintain their shape. Rigid airships feature a durable metal framework that supports their structure regardless of pressure changes.

Rigid airships feature a robust structural framework covered by an outer skin or envelope. The framework supports multiple internal gasbags or cells which provide lift. Zeppelins, the most famous rigid airships, utilize compartmentalization to enhance stability and control during flight. This design allows the lifting gas to be distributed across multiple compartments, maintaining structural integrity even when gas is partially released. Rigid airships have played roles in both military and civilian aviation history, including passenger transport and reconnaissance missions.

Blimps lack compartmentalized gasbags but use smaller air-filled ballonets to adjust buoyancy. The flexible envelope of a blimp is prone to shape changes based on gas pressure, requiring careful management of envelope integrity. Non-rigid airships are simpler and more cost-effective in design compared to rigid airships but lack the same level of structural stability. Blimps use control surfaces similar to those on heavier-than-air aircraft to stabilize and guide the craft during directional changes.

Airships achieve buoyancy through lighter-than-air gases like helium or hydrogen, which are less dense than air. Helium or hydrogen creates the necessary lift for sustained flight. Dirigible propulsion systems enable self-propulsion, while control surfaces facilitate aerodynamic control and steerability. Airship dirigibles navigate using principles of lighter-than-air craft operating principle, allowing efficient movement through the air. The ability to remain aloft for extended periods makes airships suitable for tasks like surveillance, advertising, and scientific research.

The historical importance of airships is evident in their function during wartime and peacetime operations. Zeppelins, during World War I and the interwar period, demonstrated the potential of rigid airship stability and compartmentalization. Modern blimps continue to serve practical purposes, leveraging non-rigid airship envelope integrity for flexibility. Airships are classified within the broader category of lighter-than-air craft, encompassing various designs specialized to specific missions. Understanding airship types and their unique characteristics highlights their ongoing relevance in aviation.

What are the types of airships?

The types of airships are outlined below.

- Rigid airships: Maintain their shape through a solid internal framework made of aluminum alloys, enclosing multiple gas-filled cells for buoyancy, exemplified by German Zeppelins like the LZ-129 Hindenburg.

- Semi-rigid airships: Rely on a partial structure, like a keel, to support their shape while using gas pressure for additional stability, elevating maneuverability for roles like cargo transport.

- Non-rigid airships (blimps): Depend entirely on internal gas pressure to maintain their form, utilizing flexible envelopes and ballonets to regulate pressure dynamically during flight.

- Hybrid airships: Combine traditional lighter-than-air technology with aerodynamic lift mechanisms, offering better payload capacity and efficiency for heavy-lift transport and remote logistics.

- Helium-based airships: Use helium as the primary lifting gas in modern designs, guaranteeing safety, consistent buoyancy, and operational reliability across various airship types.

The types of airships include rigid, semi-rigid, and non-rigid airships, each defined by their structural design and lifting mechanisms. Rigid airships reached lengths of up to 240 meters (787.4 feet), making them some of the largest aircraft ever constructed. Non-rigid airships rely entirely on internal gas pressure to maintain their shape, utilizing a flexible envelope design. Helium serves as the primary lifting gas in modern airships, providing safety and consistent buoyancy. These airships measure between 30 (98.43 feet) to 70 (229.66 feet) meters in length, making them suitable for localized operations like advertising and surveillance.

What is the difference between an airship and a blimp?

The difference between an airship and a blimp is explained in the table below.

Feature | Airship | Blimp |

Structural Design | Rigid or semi-rigid internal framework | Non-rigid, relies on gas pressure to maintain shape |

Shape Maintenance | Maintains shape due to rigid or semi-rigid framework, which provides stability even when deflated | Maintains shape through pressurized gas in flexible envelope |

Payload Capacity | Higher payload capacity (rigid airships can carry up to 100 tons or more historically) | Limited payload capacity, suitable for lighter tasks |

Applications | Complex missions (e.g., wartime escorts, heavy transport) | Advertising, surveillance, observation |

Envelope Design | Supported by internal framework; filled with helium for buoyancy and structural stability | Flexible envelope reliant on gas pressure for buoyancy and shape |

Propulsion Systems | Propellers or ducted fans integrated into robust design | Propulsion systems limited by non-rigid construction |

Historical Examples | Zeppelins (e.g., LZ 129 Hindenburg) | Modern advertising blimps |

Advantages | Structural integrity allows heavier payloads and complex operations | Lightweight, cost-effective, steady flight for small-scale tasks |

Disadvantages | Higher cost, complexity, and maintenance requirements | Limited payload and operational scope due to reliance on gas pressure |

Rigid airships, like the historic Zeppelins, use a lightweight metal structure to support their shape, allowing them to carry heavier payloads. Non-rigid airships, or blimps, depend entirely on helium pressurization, making them more suitable for lighter tasks like advertising or surveillance. Semi-rigid airships incorporate partial internal support, offering a balance between rigidity and flexibility in design.

Rigid airships maintain their shape through a rigid airship internal framework composed of lightweight materials. This framework ensures structural integrity regardless of gas pressure. Semi-rigid airships incorporate partial internal support, which provides a balance between flexibility and rigidity. Non-rigid airships, or blimps, rely entirely on gas pressure for non-rigid airship shape maintenance. The flexible envelope of a blimp is vital for maintaining its form and functionality. Rigid airships use a rigid airship internal framework to support their envelopes, allowing consistent performance under varying conditions. Semi-rigid airships achieve moderate payload capacities while retaining some flexibility in design. Structural differences directly impact the efficiency and capabilities of propulsion systems in both types of vehicles.

What is the difference between a blimp and an aerostat?

Differences between a blimp and an aerostat are explained in the table below.

Feature | **Blimp** | **Aerostat** |

Definition | Steerable, free-flight capable airship | Stationary, tethered lighter-than-air platform |

Structure | Non-rigid structure maintained by internal gas pressure | Flexible envelope reliant on buoyancy and tethering |

Buoyancy Mechanism | Helium or hydrogen for lift; ballonets control buoyancy during flight | Helium or hydrogen for lift; constant altitude maintained by tether length |

Mobility | Powered propulsion (e.g., propellers, ducted fans) | Tethered to fixed point; no powered propulsion |

Operational Wind Speed | Stable flight in winds <6 m/s (<20 ft/s) (<6.4 m/s) | Remains stationary with mooring lines >20 m (>65.6 ft) |

Stabilization | Shape maintained by internal gas pressure | Stabilized by tethering and mooring lines |

Primary Use Case | Mobile surveillance, advertising, research | Stationary surveillance, communication relay |

Shape Maintenance | Internal gas pressure ensures envelope integrity | Shape less critical due to tethered operation |

Research References | S. S. Bhat et al. (2024) - Autonomous blimp study | J. Breukels (2007) - Aerostat stabilization methods |

Blimps achieve free-flight using powered propulsion systems, enabling stable flight with wind speeds below 6 meters per second (20 feet per second). Aerostats remain stationary with mooring lines longer than 20 meters (65.6 feet) reducing system swaying. Both systems operate using lighter-than-air gases like helium or hydrogen for buoyancy.

How do airships work?

Airships work by combining buoyancy from lift gases, ballonet adjustments for altitude control, and mechanical systems for propulsion and stability. Helium provides buoyancy as it is lighter than air, with a density of 0.1786 kg/m³ (0.01115 lb/ft³) compared to air's 1.2 kg/m³ (0.075 lb/ft³). The gas envelope contains tens of thousands of cubic meters of helium, generating lift based on Archimedes’ principle. Ballonets adjust internal air pressure to control altitude without altering the volume of helium. Fins and rudders stabilize the airship during flight, while rudders alter airflow for precise steering. Engines generate thrust through propellers, allowing maneuverability and speed.

Airship buoyancy relies on lift gas density, with helium having a density of 0.1786 kg/m³ (0.01115 lb/ft³) and air 1.2 kg/m³ (0.075 lb/ft³). Gas envelope volume determines lift capacity, as one cubic meter of lift gas provides one kilogram of lift. Gas envelope containment ensures buoyancy by preventing leaks, while durable materials maintain envelope integrity. Ballonets pressure adjusts internal air volume to control altitude without altering lift gas volume. Volume changes enable precise altitude adjustments, allowing stable flight. Gondola payload includes passengers and cargo, while control systems manage navigation and operations. Propulsion system thrust is generated by engines, with propellers controlling directionality. Engine efficiency minimizes energy consumption, optimizing performance. Control surface’s steering and stability counteract yaw and roll movements. Rudders control airflow around the tail section, enabling smooth turns. Rudder direction adjustments guarantee precise course corrections.

Rigid airships use an internal framework to maintain shape, while semi-rigid airships rely on partial structural support. Non-rigid airships depend solely on internal pressure. Historical designs focused on military and passenger transport, with modern prototypes emphasizing surveillance and tourism. Airship stability depends on fins and rudders, which enhance aerodynamic performance. Fins resist unwanted movements, while rudders assist in steering. Airship navigation incorporates GPS for accurate positioning. Propulsion systems allow movement through thrust generation, with efficient engines conserving fuel. Airships make use of advanced materials to elevate gas envelope containment and reduce weight. Airships use both buoyant lift and mechanical systems to achieve stable flight. Airships were historically employed for long-duration missions, showcasing their ability to stay aloft for extended periods. Airships work by combining buoyancy, propulsion, and control systems into a cohesive design.

Why is helium used to fly blimps instead of hydrogen?

Helium is used to fly blimps instead of hydrogen because its non-flammable nature enhances safety. Hydrogen poses a high risk due to its flammable properties. The Hindenburg disaster demonstrated hydrogen's explosive risks during docking. Helium’s chemical stability eliminates combustion risks under normal conditions. Airship designs guarantee containment of helium to maintain its inertness.

Helium's inertness ensures stability and prevents combustion under normal conditions, making it ideal for blimps. Hydrogen flammability increases the likelihood of accidents, which concerns modern airship designers. The Hindenburg disaster remains a historical example of hydrogen’s dangers and highlights disaster safety failure. Helium gas provides 93% of hydrogen’s lift at full purity while eliminating risks associated with hydrogen explosiveness. Hydrogen’s density measures about 0.0899 kg/m³ (0.00561 lbs/ft³) at standard conditions, whereas helium’s density is 0.1785 kg/m³ (0.01115 lbs/ft³). Helium lifts roughly 1.1145 kg (2.457 lbs) per cubic meter (35.315 cubic feet) compared to hydrogen’s 1.2031 kg (2.652 lbs) per cubic meter (35.315 cubic feet) under the same conditions.

The trade-off between hydrogen’s superior lift efficiency and its catastrophic risks becomes evident through the Hindenburg disaster caused by gas containment failure. Hydrogen’s small molecular size causes leakage issues, increasing the likelihood of ignition risks. Airships rely on the lighter-than-air property of gases like helium to maintain their functionality. Helium is used widely in modern airships due to its non-flammable nature, allowing safer operations. Blimps’ lift efficiency depends on careful selection of lifting gas, where helium’s safety advantages outweigh its lower lifting capacity.

Helium is important in maintaining lighter-than-air properties while prioritizing safety through precise gas selection and containment design. Airships’ safety design focuses on preventing helium leaks effectively, assuring gas containment. Helium’s non-flammability makes it the preferred choice for airships instead of hydrogen. Helium exploits the lighter-than-air property for lift, providing a balance between safety and functionality in airship operations.

How many airships are there?

There are many airships, with 25 blimps in existence as of 2022. Approximately half of these blimps are actively used for advertising purposes. The number of operational blimps is lower, with only around 10 currently in service globally. The Goodyear Airship Group operates four of these active blimps. Non-rigid airships, which rely on internal pressure to maintain shape, represent the most common type among these vessels. Extreme weather conditions reduce operational capacity to zero due to safety concerns.

Airships are categorized into three types: non-rigid, semi-rigid, and rigid. Non-rigid airships dominate current operations, relying on internal pressure to maintain their shape. Semi-rigid airships incorporate a partial framework for structural support, while rigid airships, known as zeppelins, feature a complete internal framework. The theoretical maximum number of airships approximates 50 if including all types and conditions, though this figure accounts for non-operational vessels as well. Extreme weather conditions reduce the number of operational airships to zero due to safety concerns. Historical data reveals that airships peaked at 100 during the early 20th century, far exceeding the 25 blimps in existence as of 2022. Modern advancements enable at least one airship to achieve continuous flight for days under optimal conditions, showcasing endurance when properly maintained.

Who invented the airship?

The invention of the airship is credited to Henri Giffard, who designed and flew the first successful dirigible in 1852. Airships, a type of aerostat aircraft, evolved from hot-air balloons and advanced with contributions from pioneers like Count Ferdinand von Zeppelin and Alberto Santos-Dumont.

Henri Giffard's 1852 flight marked a pivotal moment in aviation history. The Henri Giffard first-powered airship utilized a three-horsepower (2.24 kilowatt) steam engine, enabling it to travel 17 miles (27.35 kilometers) from Paris to Trappes, France. This innovation introduced steam engine propulsion as a breakthrough in aerostatic transportation. Giffard’s design achieved a speed of five miles per hour, proving the feasibility of lighter-than-air vehicles. Non-rigid dirigibles laid the groundwork for future advancements in airship aerostatic transportation.

Count Ferdinand von Zeppelin advanced airship technology with rigid airship design. In 1900, he completed the LZ-1, a 128-meter-long vessel powered by two 16-horsepower engines. The Zeppelin airship achieved speeds of 20 miles per hour (32.19 kilometers per hour) and could carry five passengers. Count Ferdinand von Zeppelin rigid airship design reformed aviation by providing durable and navigable lighter-than-air vehicles. Rigid airships expanded the concept of practical aerostatic transportation, influencing military and commercial applications.

Non-rigid dirigibles, exemplified by Henri Giffard's work, differed from rigid structures developed by Ferdinand von Zeppelin. Giffard’s airship relied on flexible materials, while Zeppelin’s designs incorporated aluminum frames for stability. The introduction of rigid airships set new standards for airship designed structures, boosting durability and control. Both innovations contributed to establishing airships as viable modes of transport, bridging gaps between early experiments and modern advancements.

The Montgolfier brothers initiated aerostatic transportation with hot air balloons in 1783. Alberto Santos-Dumont refined airship functionality through his work on dirigibles. Contributions from these inventors defined the evolution of lighter-than-air craft. Airship aerostatic transportation continues to reflect principles established by Henri Giffard steam engine propulsion and count Ferdinand von Zeppelin aviation innovation.

What is the origin of the blimp?

The origin of the blimp is intertwined with airship innovation history. Henri Giffard achieved the first powered, controlled, and sustained airship flight in 1852 using a steam engine to drive a propeller. The term "blimp" was popularized during World War I when non-rigid airships were used for military reconnaissance and surveillance. Blimps maintain their shape due to the pressure of their lifting gas, helium, and rely on the strength of their envelope for stability. Captain Anton Heinen contributed to the U.S. Navy's dirigible fleet, marking a milestone in blimp history.

The early 20th century marked a turning point for airship aeronautics, with economic and military demands driving innovation. The need for stable observation platforms during World War I accelerated the growth of non-rigid airships. Non-rigid airship technology relied on advancements in materials like rubberized fabric and polyester film which provided durability for gas envelopes. Propulsion systems evolved from Henri Giffard's steam engine in 1852 to more efficient internal combustion engines. These innovations enabled blimps to maintain their shape through lifting gas pressure while achieving greater maneuverability and endurance.

Blimp history traces back to the broader context of airship innovation, where rigid airships like Zeppelins influenced non-rigid airship structure. Zeppelin’s structural rigidity allowed for larger designs but limited maneuverability, creating demand for flexible alternatives. The term "blimp" emerged during World War I when non-rigid airships gained prominence for reconnaissance and surveillance missions. Airship design transitioned from rigid frameworks to reliance on gas pressure and envelope strength, defining the nonrigid airship construction.

Captain Anton Heinen contributed to the United States Navy's dirigible fleet, marking a milestone in blimp history. The Navy's adoption of non-rigid airships solidified their function in military operations. United States Navy’s military adoption involved deploying blimps for anti-submarine warfare, surveillance, and reconnaissance during World War I. World War I technological impetus advanced non-rigid airship design, emphasizing lightweight construction and ease of operation. Military utility guaranteed continued operational history with blimps beyond the war, highlighting their adaptability and enduring value.

What are the key aspects of airship design?

The key aspects of airship design are outlined below.

- Aerodynamic efficiency in airship design: Reduces drag and enhances lift through optimized envelope shapes for better performance.

- Structural integration in airship design: Ensures durability with lightweight, high-strength materials while minimizing overall weight for operational functionality.

- Gas envelope retention in airship design: Relies on advanced materials to maintain internal pressure and buoyancy using helium or other lifting gases.

- Propulsion system thrust in airship design: Achieves efficient flight performance with specialized technologies to boost fuel efficiency and mission adaptability.

- Control system stability in airship design: Incorporates advanced algorithms for precise navigation and handling under varying atmospheric conditions as demonstrated in Y. Li and M. Nahon’s 2007 study on airship dynamics.

- Rigid airship design: Utilizes internal frameworks to maintain envelope shape, optimizing structural integrity for large-scale operations.

- Non-rigid airship design: Depends on internal pressure to maintain form, offering flexibility in cost-effective and lightweight applications.

- Semi-rigid airship design: Combines elements of rigid and non-rigid structures, achieving weight optimization through hybrid configurations.

- Hybrid airship design: Integrates lifting gas and aerodynamic lift generation to address payload capacity and operational efficiency issues.

- Safety systems redundancy in airship design: Incorporates rapid emergency response mechanisms to guarantee regulatory compliance and mitigate operational risks.

- Power system energy efficiency in airship design: Focuses on sustaining prolonged missions by balancing power density and energy consumption effectively.

- Landing gear durability in airship design: Enhances shock absorption and structural robustness to guarantee safe takeoffs and landings in diverse environments.

- Drag reduction in airship design: Employs techniques to minimize resistance and refine overall flight efficiency across varying speeds and altitudes.

- Payload capacity optimization in airship design: Directly influences ballast system balance and weight management to maintain equilibrium during operations.

- Design cost-weight-strength balance in airship design: Balances economic feasibility with performance requirements to overcome technological limitations.

- Atmospheric adaptability in airship design: Adapts envelope shape and structural design to operate efficiently under specific weather, altitude, and mission demands.

G. A. Khoury’s 2012 study highlights the function of modern materials’ lightweight and high strength in boosting structural design durability across airship designs. Military, commercial, and recreational airships differ in propulsion system thrust requirements and control system navigational accuracy, reflecting mission-specific adaptations. Structural integrity and advanced materials are vital for performance and functional criteria in airship operations.Technological limitations challenge envelope gas retention and structural design durability, requiring innovations in materials lightweight and materials high strength. Liao and Pasternak’s 2009 research emphasizes structural integration and optimization to minimize weight while maintaining envelope pressure stability. Time and resource allocation impact advancement processes, necessitating efficient trade-offs between performance and cost. Operating environments dictate specific design adaptations for airships. Atmospheric conditions, weather, and altitude influence envelope aerodynamic shape and structural design weight optimization. Cargo transport missions prioritize propulsion system thrust and payload capacity, while surveillance operations demand control system navigational accuracy and aerodynamics lift generation. Passenger travel requires better safety systems, emergency response and interior comfort without compromising structural robustness.

What are the parts of a blimp?

The parts of a blimp are explained below.

- Blimp envelope: Contains helium for lift, made from durable polyester or nylon, with volume determining lifting capacity and airtight seals preventing gas leakage.

- Blimp ballonets: Internal air chambers that inflate or deflate to adjust internal pressure, providing stable buoyancy and smooth altitude changes.

- Blimp gondola: Houses the cockpit, instrumentation, navigation systems, communication tools, and passenger seating, vital for safe and comfortable flight operations.

- Blimp propulsion system: Includes engines generating power and propellers converting it into thrust, often incorporating vectoring mechanisms for elevated maneuverability.

- Blimp control surfaces: Feature elevators controlling pitch, rudders managing yaw, and occasionally ailerons for roll in advanced designs, enabling precise steering and stability.

- Blimp tail assembly: Comprises stabilizers, fins, and rudders refining directional stability, balance, and overall aerodynamic efficiency during flight.

- Blimp mooring apparatus: Includes mooring cables, anchors, and tie-down systems securing the blimp to a mast or ground station during grounding or adverse weather.

- Blimp semi-rigid design: Combines an internal framework with gas pressure to maintain shape and elevate performance compared to traditional non-rigid models.

- Blimp material advancements: Utilizes modern durable materials like polyester and nylon for resistance to environmental conditions and internal pressure.

How many people can fit in a blimp?

The number of people who can fit in a blimp depends on the type of blimp, with standard advertising dirigibles accommodating up to 17 people, Goodyear blimps carrying around 12, and larger airships like the Hindenburg or Airlander 10 fitting many more. Standard Advertising Dirigibles feature seating for 2 pilots and up to 15 passengers, totaling 17 occupants. Goodyear blimps include a gondola designed for about 12 people, serving corporate guests and press. Hindenburg accommodated up to 72 passengers in its final configuration for luxury long-distance transport. Airlander 10 accommodates up to 100 people in a large gondola under the envelope. Capacity is constrained by design and operational factors including size, weight, and safety considerations.

Early 20th-century airships operated with a crew of 36 and a passenger capacity of 24. Newer airship designs expand capacities further, featuring arrangements for 5 pilots and 15-16 crew members, totaling 21 people. LMH1 Cargo Airship, based on a 20,000 kg (44,092 lbs) payload, theoretically transports around 27 people at 75 kg (165 lbs) each when converted for human use. Scaled-up LMH1 designs achieve a 500,000 kg (1,102,311 lbs) payload, hypothetically carrying 667 people at 75 kg (165 lbs) each. Larger airships demonstrate scalability, balancing engineering advancements with operational practicality.

What is a hybrid airship?

A hybrid airship is a new type of aircraft that combines heavier-than-air and lighter-than-air technologies, obtaining lift from helium, aerodynamic forces, and vectored thrust while offering an environmentally friendly and versatile solution for cargo transport and other applications. Hybrid airships obtain about 80% of their lift from helium-filled envelopes stored within the vessel's center, with the remaining 20% derived from aerodynamic forces generated by the shape of the hull. Vectored thrust from rotatable engines enhances maneuverability and enables operations in remote locations, whether on water or land. These airships are capable of carrying massive payloads, with some designs transporting up to ten tonnes of cargo efficiently. Helium, a non-combustible gas, ensures safety while reducing carbon dioxide emissions by 75% compared to conventional aircraft. Hybrid airships represent a versatile solution for cargo transport, personnel delivery, and surveillance roles in challenging environments.

Hybrid airship design combines lift buoyancy and aerodynamic lift force to achieve efficient flight. The airship envelope design incorporates materials with high strength-to-weight ratios, providing structural integrity while reducing overall weight. Airship envelope aerodynamic shape enhances airflow efficiency, minimizing drag and maximizing lift. Helium serves as the lifting gas, providing 80% of total lift due to its low density and non-flammable properties. Lifting gas safety is guaranteed by helium’s inert characteristics, making it vital for operational stability. Hybrid airship payload optimization focuses on balancing structural innovation with payload capacity, enabling transport of several tons based on mission requirements.

Propulsion system mobility in hybrid airships includes traditional engines and multiple rotatable engines for vectored thrust, boosting maneuverability and stability. Flight control mechanisms integrate advanced avionics and navigation systems to manage interactions between buoyant and aerodynamic forces during flight. Flight control stability ensures precise guidance and adaptability in diverse environments. Propulsion system fuel efficiency surpasses conventional aircraft, achieving a 75% reduction in carbon dioxide emissions. Engine thrust supports short takeoffs and landings on unprepared surfaces, expanding operational versatility. Airship envelope gas containment maintains buoyancy and structural integrity under varying conditions.

Aerodynamic lift airflow efficiency contributes the remaining 20% of total lift in hybrid airships, generated by the shape of the hull and airflow across aerodynamic surfaces. Hybrid airships combine buoyant and aerodynamic forces, enabling higher speeds and greater payload capacities compared to traditional airships. Combination of buoyant and aerodynamic lift provides unparalleled versatility in aviation, aiding missions requiring large payload capacities and access to challenging terrains. Airship envelope material strength ensures durability and performance in extreme conditions, while lifting gas density directly impacts the airship's ability to achieve lift.

Hybrid airship transport offers unique solutions for heavy-lift and long-range missions, including logistics, surveillance, and humanitarian aid delivery. Hybrid airship class includes configurations specialized for specific missions, ranging from non-rigid designs for simplicity to rigid structures for elevated durability. Hybrid airships enable access to remote areas without runways, utilizing the Air Cushion Landing System (ACLS) for operations on various terrains. Hybrid airship uses extend to personnel delivery and cargo transport, providing a vibration-free setting for sensitive payloads. Payload capacities in hybrid airships depend on envelope design and structural innovation, allowing maximum utility for transport roles.

What is a hot air airship?

A hot air airship is an aircraft that combines the thermal lift of hot air balloons with the maneuverability of powered airships, using heated air inside its envelope to generate buoyancy and achieve flight. A hot air airship generates buoyancy by heating the air inside its envelope, creating a lower air density within the interior compared to the ambient air outside. The envelope is large and made of heat- and fire-resistant materials to guarantee durability during flight. Propane burners heat the air, producing an upward force similar to helium-filled airships while relying on thermal systems instead of stored gas. Continuous heating maintains lift, and propulsion systems allow the craft to maneuver in any direction. Hot air airships combine the simplicity of hot air balloons with the advanced control of powered airships.

The principle of buoyancy in a hot air airship relies on the lighter-than-air principle, where heated air inside the envelope is less dense than the surrounding atmosphere. Burner heat production occurs through combustion, using propane, to increase the temperature of the air within the envelope. The envelope material must maintain structural integrity while securely containing the heated air, assuring minimal heat loss during flight. Airship lift generation depends on this density difference, as the heated air creates an upward force that counteracts gravity.

The design and structural components of a hot air airship include a large envelope made from lightweight, fireproof synthetic fabrics. The envelope's shape and size directly influence aerodynamic efficiency and lift capacity. The gondola control cabin serves as the central hub for crew operations, housing instrumentation, controls, and passengers. Gondola payload capacity is determined by the airship’s size and the efficiency of its heating system, balancing weight distribution for stable flight.

Flight control and propulsion systems are vital for maneuverability in hot air airships. Propulsion system thrust is generated by engines driving propellers or fans, enabling directional control and overcoming wind resistance. The propulsion system engine performance ensures sufficient power to achieve controlled flight. Hot air airship flight control involves continuous adjustments to burner combustion and engine settings, allowing precise navigation and altitude management.

Operational aspects of a hot air airship require careful monitoring of hot air temperature and pressure within the envelope. The crew manages burner combustion to regulate lift and maintain buoyancy. Airship aerodynamics are pivotal in maintaining stability, with the envelope structural integrity and gondola placement affecting overall performance. Hot air airship operation demands coordination between thermal inputs, propulsion, and environmental conditions to guarantee safe and efficient flights.

How far can a blimp travel?

A blimp can travel distances ranging from 150 (241.4 kilometers) to 200 (321.8 kilometers) miles per day, depending on its design and operational conditions. Blimps achieve extended flight distances of 350 to 400 nautical miles during optimal conditions at speeds of 45 knots. Maximum speed reaches up to 100 knots (185.2 kilometers per hour) with robust engines, though cruising occurs at 35 miles per hour (56.3 kilometers per hour) in zero wind. Refueling becomes necessary after traveling 250 miles (402.336 kilometers) due to fuel capacity limitations. Continuous flight duration extends up to 14 hours for most designs, influenced by mission requirements and operational constraints.

How long can a blimp stay in the air?

The duration a blimp can stay in the air depends on its design, mission requirements, and operational conditions.Short-duration flights last around 1 hour, used for tasks like local surveillance or promotional events. Many standard blimps operate for up to 24 hours without refueling, suitable for routine operations. With onboard fuel and favorable weather conditions, blimps achieve flight durations of 3 days, used for extended surveillance missions. Advanced airships designed for long-term observation remain airborne for 14 days, relying on efficient fuel management systems and optimal operational conditions. Experimental airships, under ideal scenarios with advanced technology, reach a theoretical maximum endurance of 21 days.

Short-duration flights lasting around 1 hour for specific tasks like local surveillance or promotional events. These missions require minimal fuel and rely on lightweight designs optimized for quick deployment. Standard operational durations of up to 24 hours without refueling are achieved by many conventional blimps. These durations suit routine operations like aerial patrols or commercial advertising. With onboard fuel and favorable weather conditions, blimps achieve flight durations of 3 days. This capability is vital for tasks requiring prolonged observation or scientific data collection.

Advanced airships designed for long-term observation missions remain airborne for 14 days. These airships incorporate efficient fuel management systems and robust helium retention mechanisms. Helium retention and minimal leaks are decisive factors enabling endurance of up to 7 days. The quality of the envelope material and precision in engineering play a part in achieving this performance. Experimental or specially designed airships with full tanks and optimal conditions push endurance limits to 21 days. These airships utilize cutting-edge technology and innovative designs to maximize operational efficiency.

Certain modern hybrid airships under ideal scenarios achieve a theoretical maximum endurance of 3 weeks. Technological advancements and operational efficiency are key determinants in reaching this milestone. Blimp pilots guarantee safe navigation and precise control during extended missions. Blimps stay aloft longer when equipped with advanced systems that optimize fuel consumption and helium management.

How fast is a blimp?

A blimp’s ranges from 35 mph (56.3 km/h) in calm conditions to over 70 mph (112.7 km/h) for the latest models. Blimps cruise at speeds of 40 mph (64.4 km/h) under optimal conditions. Older Goodyear Blimp models achieve a maximum speed of about 50 mph (80.47 km/h), while newer models like the Zeppelin NT reach top speeds of 73 mph (117.48 km/h). Advanced blimp models attain speeds up to 78 mph (125.52 kph) in ideal conditions. The highest officially measured speed for airships reaches 115 km/h (71.45 mph), with faster models potentially achieving speeds of 150 km/h (93.21 mph). Environmental factors and design advancements influence blimp speed capabilities.

How big is a blimp?

A big blimp can measure up to 804 feet (245 meters) in length, depending on its model and purpose. The Goodyear Blimp GZ-20 measures 192 feet (58.5 meters) in length, 59.5 feet (18.1 meters) in height, and 50 feet (15.2 meters) in width. The Zeppelin NT measures 246.4 feet (75.1 meters) in length and accommodates up to 15 passengers. The Hindenburg airship measures 804 feet (245 meters) in length and 135 feet (41 meters) in diameter. Modern technically sophisticated airships measure up to 420 feet (128 meters) in length.

Smaller blimp models like the Goodyear Blimp GZ-20 measure 105.5 feet (32.15 meters) in length. The Goodyear Blimp GZ-22 exceeds the older GZ-20 model by 52 feet (16 meters) in length. Maximum diameter of smaller blimps measures 31 feet (9.4 meters) whereas larger advanced models range between 38 feet (11.6 meters) and 11.6 meters (38 feet) in diameter. Enormous blimps possess an internal volume of 297,527 cubic feet and accommodate up to 14 people. Smaller blimp models achieve a maximum speed of 50 mph (80.47 km/h) while larger blimps cruise at 40 mph (64.37 km/h) and reach top speeds of 80 mph (128.75 km/h).

How do blimps land?

Blimps land through precise coordination of the pilot's skills, the blimp's mechanical systems, and the ground crew's assistance. The envelope of a blimp maintains consistent buoyancy and structural integrity during landing. Ground crew attaches mooring lines to secure the blimp to a fixed mast or turntable. Pilots manage descent paths by adjusting ballonets to control air-to-helium ratios. Propulsion systems maintain directional stability while rudders align the blimp with wind direction. Safety protocols guarantee clear roles and protect the crew, reducing risks during landing operations.

Controlled descent begins with the pilot reducing altitude while maintaining a steady approach path. Blimp envelope integrity ensures consistent buoyancy and pressure during this phase. Pilots adjust ballonets to regulate air-to-helium ratios, achieving negative buoyancy for descent. Water ballast fine-tunes weight distribution, stabilizing the blimp during descent. Propulsion system thrust control manages forward motion, decelerating the airship as it nears the landing site. The rudder aligns the blimp with wind direction, while the elevator adjusts pitch for a smooth approach. Descent path involves gradual reduction in altitude, adhering to approach protocols that prioritize safety. External factors like wind speed, visibility, and weather conditions influence landing strategies. Pilot decision-making assesses these variables to guarantee safe operations. Safety protocols establish clear roles for ground crew mooring assistance and ground crew safety operations.

Pilots maintain primary responsibility for landing, aided by automated systems. Pilot operational skill ensures precise control over aerodynamic controls, propulsion adjustments, and ballonet management. Ground crew secures mooring lines to a fixed mast or turntable, preventing wind-induced movement. Communication between pilots and ground crew remains vital for coordinating actions. Gas regulation and ballast system weight distribution maintain stability throughout the process. Maximum descent rates for airships reach around 1200 feet (365.76 meters) per minute, but actual rates remain lower for safety considerations. Deceleration reduces speed near the landing site, guided by visual references and navigation aids. Engine stabilization assists in managing speed and directional stability during final stages of descent. Blimp flying demands adherence to protocols, guaranteeing every part functions harmoniously for a controlled landing.

Are blimps safe?

Blimps are safe due to their structural integrity, gas envelope durability, and advanced safety features. Modern blimps use non-flammable helium, eliminating the fire risks associated with hydrogen. Advanced materials enhance gas envelope durability, providing structural integrity under extreme conditions. Redundant propulsion systems maintain safe flight even during engine failures. Regulatory agencies enforce strict safety protocols, including regular inspections and pilot training standards. Weather monitoring systems detect adverse conditions, enabling safer flight planning.

Passenger safety in blimps aligns closely with crew and cargo transport standards due to gas envelope integrity and propulsion system redundancy. Military applications emphasize emergency systems fail-safes and weather monitoring forecasting, guaranteeing compliance with regulatory agencies oversight. Civilian operations prioritize airship aerodynamics and maintenance practices compliance, achieving high safety regulations standards. Accident probability remains low, with structural resilience demonstrated through advanced materials elevating gas envelope durability.

Operational conditions like extreme weather require robust blimp structural integrity and propulsion system reliability. During takeoff, flight, and landing phases, ballast control and backup power sources maintain blimp stability. Routine operations benefit from redundant engines backing blimps systems, while emergency scenarios rely on advanced technology and regulatory agencies inspection protocols. Weather monitoring detection systems are vital in avoiding adverse flight conditions, assuring safe routes for both military and civilian applications.

Key factors influencing blimp safety include design features like semi-rigid internal structures distinguishing blimps dirigibles from non-rigid designs. Engineering advancements focus on airship safety features, incorporating efficient aerodynamic design to optimize blimps flight. Maintenance inspection ensures gas envelope integrity under varying conditions, backed by strict safety protocols governing operational standards. Crew expertise enhances emergency systems redundancy, addressing issues in dynamic environments. Helium eliminates fire risks associated with hydrogen, further elevating safety across all contexts.

Are blimps bad for the environment?

Blimps are not bad for the environment, as they reduce carbon emissions and fuel consumption through helium lift and hybrid technology, though helium scarcity threatens their long-term sustainability. The Airlander 10 reduces carbon emissions by up to 90% compared to conventional aircraft. Helium lift minimizes fuel consumption, lowering the environmental impact. Hybrid engines enhance fuel efficiency, reducing fossil fuel combustion. Blimps produce less than 1% of the CO₂ emissions generated by long-haul cargo flights. Lightweight materials and advanced aerodynamics further decrease energy requirements.

Greenhouse gas emissions from blimps remain lower compared to conventional aircraft. Noise pollution levels are minimal due to advanced airship design and hybrid-electric propulsion systems. Wildlife disturbance is reduced as blimps operate at lower speeds and altitudes, avoiding the high-altitude flight paths that disrupt migratory patterns. The ecological footprint includes manufacturing lightweight materials, which lowers energy requirements during production. End-of-life disposal focuses on recycling advanced materials, minimizing waste in the environment ecosystem.

Manufacturing involves fossil fuels combustion, but the use of lightweight materials reduces energy consumption. Operational use highlights blimps’ fuel efficiency through helium lift and hybrid engines. Helium scarcity poses issues for long-term sustainability, yet responsible sourcing mitigates some risks. Recycling components like solar panels and electric systems supports eco-friendliness. Airships’ innovation ensures continuous improvement in reducing the overall environmental impact pollution.

Carbon emissions emission levels of blimps are 75%-90% lower than those of airplanes. Energy efficiency improves through aerodynamic designs and reduced weight. Pollution levels decrease as blimps produce less than 1% of CO₂ emissions generated by long-haul cargo flights. Impacts on ecosystems and biodiversity are minimal due to low noise and slow flight speeds. Blimps contribute to better environment air quality by reducing fossil fuels resource depletion.

Airplanes emit 2.4% of global carbon emissions, whereas blimps achieve reductions in blimps emissions. Helicopters consume more fuel per passenger mile, increasing their carbon footprint. Drones rely heavily on battery technology, which raises concerns about resource extraction. Blimps excel in fuel efficiency and reduce dependency on fossil fuels combustion. Hybrid Air Vehicles and Goodyear blimps showcase advancements in sustainability, renewability and airship aerodynamics.