Glider Plane: Definition, Difference, Performance, Function

Jim Goodrich • • Reading time: 48 min

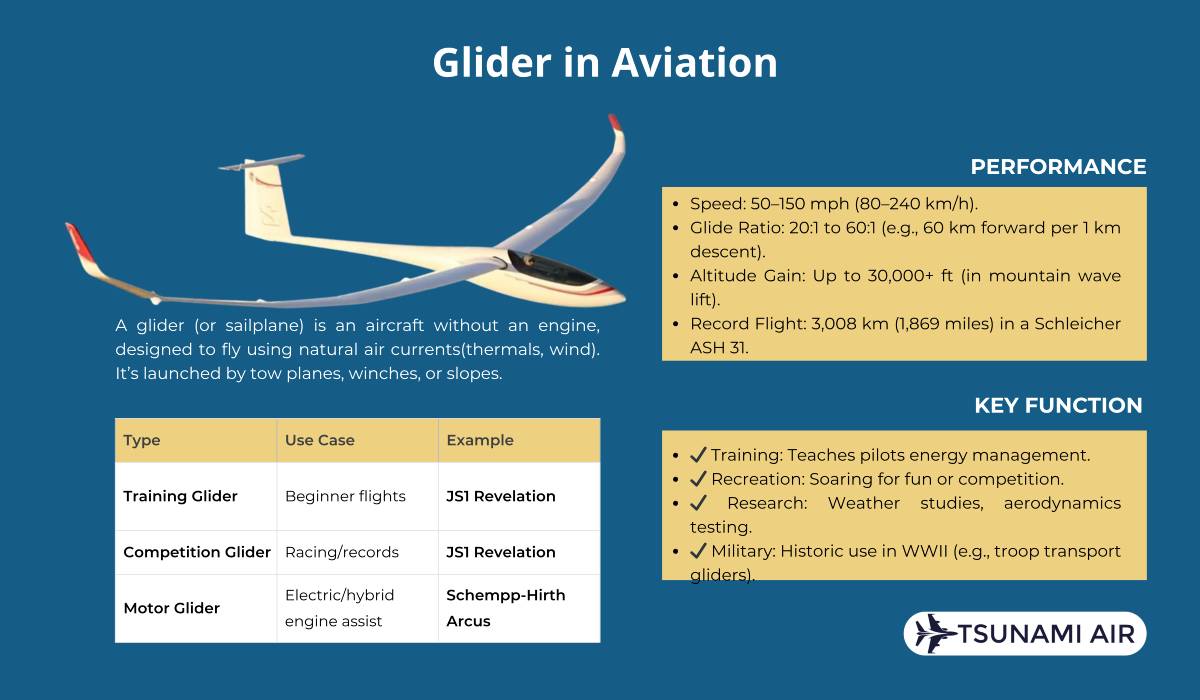

A glider plane is an aircraft designed for sustained flight without the use of power. The glider plane relies on its wings and control systems to maintain lift and stability during flights. Pilots operate the machine by utilizing precise aviation techniques to manage its dimensions and shape. The glider plane's performance depends on its wing design and efficient control mechanisms. Understand the glider plane's model, flight characteristics, and relation to powered aircraft.

Gliders and sailplanes differ in performance capabilities and design sophistication. Gliders emphasize simplicity and recreational use, featuring basic structural designs suitable for short-duration flights. Sailplanes incorporate advanced aerodynamics with high-aspect-ratio wings and refined airfoil shapes, achieving glide ratios exceeding 50:1. The Nimeta X achieves a glide ratio over 70:1. Lightweight composite materials like carbon fiber enhance structural integrity while reducing weight in sailplanes.

Glider flight durations vary based on glider type, weather conditions, and pilot skill. Recreational flights extend between 1 to 5 hours, relying on pilot experience and favorable weather. Optimal soaring conditions enable flights to last up to 16 hours through skilled navigation of atmospheric patterns.

Gliders operate by leveraging aerodynamic principles to generate lift and minimize drag. Long, slender wings with high aspect ratios optimize aerodynamic efficiency, reducing induced drag. Airfoil geometry ensures smooth airflow, creating pressure differences that produce lift. Modern gliders achieve glide ratios exceeding 50:1, allowing travel of 50 meters (164 feet) horizontally for every meter (3.28 feet) of altitude lost. Pilots use rising air currents like thermals and ridge lift to gain altitude and extend flight durations. Control surfaces like ailerons, elevators, and rudders enable precise adjustments to roll, pitch, and yaw, assuring stable and maneuverable flight.

Key considerations for glider plane design focus on aerodynamic efficiency and structural optimization. Wing design geometry includes elliptical, rectangular, tapered, or swept-forward planforms, impacting drag and lift generation. High aspect ratios reduce induced drag, bettering span efficiency during flight. Airfoil selection balances lift and minimizes profile drag, with cambered profiles deflecting airflow downward to create lift. Structural integrity ensures durability under varying airspeed and weight distribution loads. Materials with high strength-to-weight ratios, like carbon fiber, optimize performance without compromising safety. Weight distribution stabilizes flight, with water ballast adjusting the center of gravity for boosted airspeed and lift-to-drag ratio performance.

The parts of a glider include the wing, fuselage, tail, horizontal and vertical stabilizers, cockpit, landing gear, ailerons, and airbrakes. The wing spans 8–11 meters (26.25–36.09 feet) and provides lift through its airfoil shape. The fuselage ensures structural integrity and houses the cockpit, distributing weight evenly. Horizontal and vertical stabilizers maintain pitch and directional stability during flight. Ailerons control roll, while airbrakes manage descent speed and drag. Landing gear focuses on shock absorption, with conventional gliders using fixed or retractable wheels. Hang gliders rely on tethers and a control bar for maneuverability, enabling pilots to manage pitch and roll by shifting body position relative to the wing.

What is an air glider plane?

An air glider plane is an unpowered aircraft that relies on the dynamic reaction of air against its long, slender wings to stay airborne and glide without the need for an engine. Gliders lack engines and rely on meteorological phenomena like thermals to stay airborne. Long, slender wings characterize gliders, maximizing lift and minimizing sink rate aerodynamically. Pilots use gliders for the sport of gliding or soaring activity, utilizing rising air currents to maintain altitude. Sailplanes, a type of glider specifically designed for soaring, achieve sustained flight using weather phenomena like ridge and wave lift. Self-launching motor gliders incorporate small engines to provide additional support during initial elevation gain.

The design and structure of glider planes emphasize lightweight airframes and aerodynamic efficiency. Long, high-aspect-ratio wings reduce drag while maximizing lift generation. Sailplanes achieve glide ratios exceeding 50:1, with the Nimeta X reaching over 70:1. Fuselages are sleek, and pilots sit semi-prone to minimize cross-sectional area. Modern materials like carbon fiber guarantee strength while reducing weight, contributing to unpowered flight lift-generation. Wing spans vary, with high-performance sailplanes featuring spans up to 30 meters (98.43 feet). Increased span improves the lift-to-drag ratio, elevating flight performance and glide efficiency.

Aerodynamic principles govern lift production in unpowered flight. Airflow moves faster over the curved upper surface of the wing, reducing pressure and creating upward force. Lift counteracts the aircraft's weight, enabling sustained flight. High lift-to-drag ratios, exceeding 40:1 in modern sailplanes, reflect optimized aerodynamic airflow. Glide ratios quantify horizontal travel per altitude lost, with a 50:1 ratio indicating 164.04 feet of forward movement for every 3.28 feet of descent. Sink rates depend on wing design and air density, with low sink rates extending flight duration through efficient energy conservation.

Energy conservation during unpowered flight relies on natural meteorological phenomena. Thermals, ridge lift, and wave lift provide rising air currents that allow gliders to gain altitude. Pilots exploit thermals during gliding thermal riding, conserving energy by avoiding engine use. Rising air currents enable extended soaring sessions under optimal conditions. Sink rate management ensures minimal altitude loss, while efficient lift-to-drag ratios maximize horizontal distance covered. Sailplane efficiency depends on utilizing these natural forces to maintain altitude and prolong flight.

Control surfaces, including ailerons, elevators, and rudder, guarantee maneuverability and stability during flight. These aircraft control surfaces regulate roll, pitch, and yaw, maintaining precise control over gliding aerodynamic principles. Gravity drives forward motion as gliders descend, converting potential energy into kinetic energy. Adjusting the glide slope manages descent rates, with lift and drag influencing trajectory. Gravity utilization allows gliders to cover hundreds of kilometers efficiently, relying solely on aircraft configuration and environmental factors.

What is a cargo glider?

A cargo glider is an engineless aircraft designed to transport troops, equipment, and supplies, often used in military operations for silent and stealthy delivery in combat zones. Cargo gliders operate without engines, relying on towing by powered aircraft to gain altitude before release. Military gliders deliver troops and supplies silently into combat zones, making them ideal for stealth operations. The Waco CG-4A carries up to 15 soldiers or 3 tons of cargo. Militaries deploy cargo gliders in remote or heavily defended areas where conventional aircraft face higher risks. Aerocart’s automated glider systems now aim to triple payload capacity, elevating efficiency in cargo transport.

High-aspect-ratio wings generate lift in cargo gliders, enabling efficient unpowered flight. Glide ratios determine horizontal distance traveled per unit of altitude loss, with cargo gliders achieving practical values for mission requirements. Control surfaces like ailerons, spoilers, and rudders guarantee maneuverability during flight. Structural design minimizes weight while maximizing strength, historically utilizing wood and fabric materials. Modern cargo glider manufacturers incorporate advanced composites to enhance structural efficiency and payload capacity. Aerodynamic performance remains uncompromised, allowing cargo gliders to maintain stable flight under heavy payloads.

Cargo glider flight relies on tow planes or natural lift sources like thermals for initial ascent. Upon release, control surfaces stabilize navigation through precise handling. Airborne delivery benefits from silent deployment, making cargo gliders ideal for stealth operations in combat zones. Payload capacity varies by design, with the Waco CG-4A carrying up to 15 soldiers or 3,750 pounds (1,701 kilograms) of cargo. Aerocart’s automated systems aim to triple payload capacity, refining cargo transport logistics. Military glider troop capacity prioritizes rapid deployment over pure cargo volume.

Manufacturers like Waco Aircraft and General Aircraft developed cargo gliders extensively during wartime. The Waco CG-4A featured large cargo bays accommodating troops, jeeps, or equipment. Tactical deployment behind enemy lines relied heavily on these unpowered aircraft. Airborne logistics supply chains depended on cargo gliders for delivering supplies to remote areas. Difficult-to-access operational zones received direct deliveries via cargo gliders, showcasing their importance in airborne logistics cargo delivery. Strategic advantages arose from rapid deployment capabilities during campaigns like the Normandy landings.

What is the difference between a glider and a sailplane?

Differences between a glider and a sailplane are explained in the table below.

Criteria | Glider | Sailplane |

Definition | Non-powered aircraft designed for recreational use. | High-performance glider with refined aerodynamics. |

Purpose | Recreational soaring and general aviation. | Competitive and cross-country soaring. |

Lift-to-Drag Ratio | Moderate; typically lower than sailplanes. | Superior; exceeding 30:1 in high-performance models. |

Wing Design | Basic design; lower aspect ratio wings. | High aspect ratio wings with advanced airfoil shapes. |

Materials | Lightweight materials like aluminum or fiberglass. | Composite materials like carbon fiber for strength. |

Drag Reduction | Standard aerodynamic efficiency. | Up to 12% drag reduction due to optimized design. |

Distance Capability | Limited by design; typically shorter flights. | Up to 1,000 km (621.371 miles) in long-duration flights. |

Flight Duration | Shorter durations suited for casual use. | Extended flight durations for competitive environments. |

Control Surfaces | Basic control surfaces for stable flight. | Meticulously crafted for efficient and stable flight. |

Target Audience | General aviation enthusiasts seeking simplicity. | Skilled pilots focused on performance and competition. |

Gliders rely on thermal lift and ridge lift to maintain altitude, enabling sustained flight without an engine. Pilots flying gliders achieve performance levels based on the aircraft's design ratings, which cater to general aviation enthusiasts seeking accessible soaring experiences. The structural design of gliders prioritizes lightweight materials while maintaining vital control surfaces for stable flight. Sailplanes are designed to fly with high-performance capabilities, incorporating refined aerodynamics and efficient wing design. These aircraft feature high aspect ratio wings and advanced airfoil shapes, which enhance lift generation and elevate the lift-to-drag ratio. According to M. Maughmer's 2003 study, optimizing wing aspect ratio and airfoil design enables sailplanes to achieve superior aerodynamic efficiency. Sailplanes leverage thermal lift and ridge lift for extended soaring, covering distances of up to 1,000 km (621.371 miles) during long-duration flights. Lightweight composite materials like carbon fiber reduce weight while increasing structural integrity. Aerodynamic efficiency ensures sailplanes excel in competitive and cross-country soaring. Enhanced flow dynamics reduce drag by up to 12%, as demonstrated in N. J. Pfeiffer's 2017 study.

The use of advanced materials optimizes wing lift generation and structural design, allowing skilled pilots to maximize flight duration and distance. Control surfaces in sailplanes are meticulously crafted to guarantee stable and efficient flight, distinguishing them from simpler glider designs. Gliders cater to simplicity and accessibility, making them suitable for recreational use. Sailplanes are engineered for high-performance soaring, achieving superior metrics in distance coverage and flight duration. Aerodynamic principles and structural optimization enable sailplanes to outperform traditional gliders in competitive environments, underscoring the significance of advanced engineering in modern sailplane design.

Do gliders have engines?

Some gliders incorporate engines for self-launching or sustaining flight. Traditional gliders rely solely on unpowered flight, utilizing rising air currents like thermals or ridge lift to stay aloft. Motor gliders integrate small engines, ranging from 60 to 75 horsepower, to enable self-launching or sustain flight during insufficient lift conditions. Self-launching gliders use retractable engines that fold away after reaching the desired altitude, minimizing drag. Propellers in these gliders fold flat against the fuselage during unpowered flight. Sustainer engines in certain motor gliders help pilots return to base when natural lift is scarce.

Traditional gliders emphasize unpowered flight through aerodynamic efficiency and rising air currents. Motor gliders integrate engines for specific purposes like self-launching or sustaining flight during insufficient lift conditions. Engines in motor gliders range from 60 to 75 horsepower and operate as auxiliary power sources. Self-launching glider onboard engines enable independent takeoff, retracting after reaching altitudes between 1,000 (3,280.84 feet) to 2,000 (6,561.68 feet) meters. Tow plane engine propulsion provides thrust for traditional gliders during initial lift-off, towing them to desired altitudes. Glider engines include internal combustion engines and electric motors, with electric engines offering alternatives to conventional fossil fuels.

Engines are not standard equipment in traditional gliders but serve as optional modifications in motor gliders and self-launching gliders. Pilots deactivate sustainer engines during unpowered flight to minimize drag. Propellers in self-launching gliders fold flat against the fuselage to reduce aerodynamic resistance. Motor glider hybrid propulsion combines soaring efficiency with engine reliability, allowing adaptability in varying atmospheric conditions. Scenarios like returning to base or achieving altitude independently highlight the importance of glider power in modern designs.

How to become a glider pilot?

To become a glider pilot follow the steps explained below.

- Meet the minimum age requirement of 16 years to begin glider pilot training.

- Have a valid medical certificate to guarantee fitness for flight.

- Obtain a valid medical certificate to confirm fitness for flight as per aviation regulatory standards.

- Enroll in an accredited glider flight school to access certified instructors and structured training.

- Complete ground school training to study aerodynamics, weather patterns, and aviation regulations.

- Pass the FAA Private Pilot Glider written exam to demonstrate theoretical knowledge.

- Log at least 10 hours of flight time, including a minimum of 2 hours of solo flight experience.

- Perform a minimum of 20 supervised glider flights to meet practical training requirements.

- Develop skills in glider performance, navigation techniques, and emergency procedures under instructor guidance.

- Practice energy management and stick-and-rudder skills to enhance flight proficiency.

- Track logged flight hours to guarantee compliance with aviation regulatory authority standards.

- Pass the practical flight test to demonstrate operational competence and readiness for licensing.

- Join a glider club to access aeroclub facilities, shared resources, and engagement opportunities.

- Participate in aeroclub training programs to refine skills under experienced glider flight instructors.

- Regularly review ground school curriculum to reinforce theoretical knowledge and prepare for exams.

- Ensure glider airworthiness is maintained to align with safety and regulatory standards during operations.

How long can a glider stay in the air?

The time a glider can stay in the air depends on factors like glider type, weather conditions, and pilot skill. Training flights last 20-30 minutes, focusing on teaching basic gliding skills near the airfield. Recreational flights extend between 1 to 5 hours, depending on pilot experience and weather conditions. Thermal flights allow gliders to stay aloft for 8 hours by utilizing rising air currents. Optimal soaring conditions enable gliders to remain airborne for up to 16 hours through skilled navigation of thermal currents and wind patterns. The record for the longest single-seater glider flight is just over 56.25 hours, achieved in the French Alps during the 1950s.

Short-duration glider flights include training sessions lasting 20-30 minutes, designed to teach basic gliding skills near the airfield. Recreational flights range from 1 to 5 hours, relying on pilot experience and favorable weather conditions. Extended flight durations reach up to 8 hours when gliders utilize thermal currents for lift, while optimal soaring conditions allow flights to last 16 hours through skilled navigation of atmospheric patterns. Record-breaking achievements highlight the capabilities of gliders, with a single-seater glider staying airborne for 56.25 hours in the French Alps during the 1950s. A two-seater glider achieved a flight duration of 71 hours in Hawaii in 1961. Covering a distance of 1,000 km (621.371 miles) remains an aspirational goal requiring extended flight times spanning days or weeks under expert piloting and consistent lift sources. Theoretical scenarios suggest a glider stays airborne indefinitely in persistent favorable conditions with continuous lift, though practical issues like pilot fatigue and weather variability limit this possibility. Glider pilots rely on their expertise in atmospheric dynamics to maximize flight durations and achieve remarkable endurance feats.

How high do gliders fly?

Gliders’ flying height depends on weather conditions, location, and glider type, with typical altitudes ranging from 1,000 (304.8 meters) to 76,000 (23,164.8 meters) feet. Glider flights reach altitudes between 4,000 (1,219 meters) and 6,000 (1,829 meters) feet during a UK summer, limited by cloudbase height. Very low cloudbase conditions restrict flight altitudes to 1,000 feet (304.8 meters) in poor weather. Training flights release gliders at 3,000 feet (914.4 meters) for maneuver practice. Strong wave lift conditions enable gliders to soar up to 35,000 feet (10,668 meters).

Regulatory constraints impose a ceiling of 17,999ft (5,486m) without ATC permission in many regions, guaranteeing safe integration with controlled airspace. Strong wave lift conditions enable gliders to soar up to 35,000ft (10,668m), utilizing rising air currents effectively. Exceptional altitude achievements include the Black Mountains Gliding Club’s record of 32,000ft (9,753.6m) facilitated by favorable wave lift conditions. Possible altitude in extreme wave soaring conditions reaches 8,000m (26,247 feet), showcasing the potential of gliders under optimal meteorological circumstances. The world record altitude achieved by the Airbus Perlan glider stands at 50,172ft (15,292m), demonstrating the upper limits of glider performance.

How far can a glider fly?

The distance a glider can fly depends on rising air availability, glider design, and flight conditions. Pilot skill and weather conditions directly impact the distance a glider achieves. Training flights cover 5-15 miles (8-24 kilometers) without relying on lift. Cross-country and competition flights reach 100-200 miles (160-320 kilometers) by utilizing rising air currents. Exceptional flights, namely Klaus Ohlmann's 2003 world record of 3,008 km (1,869 miles), demonstrate the potential with optimal conditions. Glide ratios range from 8 to 10 km (5 to 6.2 miles) per 1,000 feet (304.8 meters) of height lost, depending on glider design and atmospheric factors.

Training flights stay within 5-15 miles (8-24 kilometers) without relying on lift. These flights occur over the airport and rarely exceed this range due to the absence of rising air currents. Glider design and pilot skill play minimal roles in such scenarios as the primary objective involves basic flight training. Rising air availability remains a limiting factor, restricting the distance covered during these initial learning stages.

Cross-country and competition flights cover 100-200 miles (160.93-321.87 kilometers) by utilizing rising air currents. Experienced pilots achieve distances of at least 300 miles (482.8 kilometers) under favorable weather conditions. Thermals and mountain waves enable gliders to maintain altitude and extend their range. Glide ratios ranging from 8 to 10 km (5 to 6.2 miles) per 1,000 feet (304.8 meters) of height lost directly influence the achievable distance. Average flights with experienced pilots and good weather cover 200-300 km (124-186 miles), showcasing the balance between pilot expertise and atmospheric factors.

Klaus Ohlmann set a world record in 2003 by flying 3,008 km (1,869 miles) using mountain waves in South America. UK flights have reached up to 620 miles (997.784 km) while long-distance flights have achieved 1,000 km (621.371 miles). Exceptional flights exceeding 3,000 km (1,864 miles) demonstrate the impact of optimal conditions and advanced glider design. Gordon Boettger and Bruce Campbell achieved a new world record in 2023 by flying 3,055 km (1,900 miles), surpassing previous milestones in glider aviation history.

What is a glider's glide ratio?

A glider's glide ratio is the horizontal distance it travels compared to the altitude it loses. A glide ratio of 20:1 means the glider covers 20 units of distance for every unit of altitude lost. High-performance gliders achieve a glide ratio of 70:1 under optimal gliding conditions. Advanced competition gliders attain a glide ratio of around 50:1 in ideal atmospheric conditions. Typical training gliders have a glide ratio of about 30:1 in smooth air. Glide ratios vary depending on the type of glider, environmental conditions, and design factors.

Near-perfect thermal lift conditions elevate elite sailplanes to a glide ratio of 60:1, whereas modern recreational paragliders achieve a glide ratio of 8:1 in still air at trim speed. Adverse weather with headwinds or downdrafts reduces the glide ratio to around 5:1, highlighting the importance of external conditions.

Moderate wind and turbulence lower the glide ratio for mid-range gliders to 20:1, while heavy crosswinds reduce stability and performance, resulting in a glide ratio of 15:1. Strong tailwinds aiding forward motion enhance high-efficiency gliders to achieve a glide ratio of 40:1. Beginner paragliders or hang gliders have an average glide ratio of 10:1 due to less optimized designs and limited skill requirements. The contrast between beginner and advanced gliders underscores the impact of design sophistication and pilot expertise on achieving higher glide ratios.

Environmental factors like wind direction, thermal lift, and turbulence interact closely with glider design to determine glide ratio outcomes. Wing aspect ratio, airfoil shape, and wing loading influence the glider's aerodynamic efficiency. A glider flying at its optimal speed maximizes the distance covered per unit of altitude lost, guaranteeing efficient unpowered flight. Pilots rely on understanding these dynamics to identify the best glide speed and adapt to altering air conditions. Glide ratios serve as a key metric for assessing aerodynamic performance and optimizing flight planning under diverse scenarios.

How do gliders work?

Gliders work by leveraging aerodynamic principles to generate lift and minimize drag, allowing them to stay aloft using natural forces like thermals and ridge lift. Gliders maintain lift through their long, slender wings, which have a high aspect ratio to optimize aerodynamic efficiency. Airfoil geometry ensures smooth airflow over the wings, generating lift by creating a pressure difference between the upper and lower surfaces. Pilots use rising air currents like thermals, created by uneven heating of the Earth's surface, to gain altitude and extend flight durations.

Full-size sailplanes, hang gliders, and model or paper gliders represent distinct categories of glider types. Full-size sailplanes are designed for high-performance flights, achieving glide ratios exceeding 50:1. Hang gliders feature a simpler, flexible wing structure with lower glide ratios around 10:1. Model or paper gliders demonstrate basic aerodynamic principles but lack the structural sophistication of larger gliders. Recreational gliding emphasizes enjoyment and traversing, while competitive gliding focuses on maximizing distance, speed, or altitude using thermals and ridge lift. Pilots in competitive settings rely heavily on precise control surfaces configuration and a deep understanding of weather patterns to optimize performance.

A glider operates through the interplay of lift, drag, weight, and gravity force. Lift force counters weight, guaranteeing the glider stays aloft. Drag resistance opposes forward motion, requiring aerodynamic efficiency to minimize energy loss. Airfoil geometry and profile generate lift by creating a pressure difference between the upper and lower wing surfaces. High-aspect-ratio wings reduce induced drag, elevating glide ratio efficiency. Gravity acceleration constantly pulls the glider downward, necessitating continuous lift generation. Tail stability and balance prevent unwanted pitching moments, maintaining steady flight conditions.

Thermal updrafts and ridge lift provide rising air currents that extend flight duration. Thermal convection occurs due to uneven heating of the Earth's surface, creating buoyant forces that pilots exploit to gain altitude. Ridge lift forms when wind encounters a mountain or hill, deflecting air upward. Glider pilots must identify and utilize these natural forces to stay aloft. Control surfaces’ effectiveness ensures precise adjustments to roll, pitch, and yaw, enabling stable and maneuverable flight in varying atmospheric conditions.

Key components of glider structure include high-aspect-ratio wings, lightweight materials, and efficient control systems. Wing span and design focus on maximizing lift while minimizing drag resistance. Airfoil geometry ensures smooth airflow, reducing turbulence and bettering aerodynamics flow. Structural materials like carbon fiber and aluminum alloys enhance strength without adding excessive weight. Drag coefficient measures resistance relative to shape and size, with lower values indicating superior efficiency. Glide ratio performance reflects the distance traveled horizontally per unit of altitude lost, influenced by wing profile and control surfaces configuration. Tail balance provides stability, guaranteeing safe and efficient flight under diverse conditions.

How do hang gliders work?

Hang gliders work by utilizing aerodynamic principles to generate lift and minimize drag, allowing them to stay aloft through pilot control and environmental factors. Hang gliders generate lift through airfoil-shaped wings with a curved upper surface, creating a pressure differential as air flows faster above the wing. The angle of attack directly influences lift production, with optimal angles providing efficient airflow and upward force. Modern hang gliders achieve glide ratios between 12:1 and 18:1 by minimizing drag, with drag coefficients ranging from 0.03 to 0.05 at cruising speeds. Pilots control the glider using weight-shift mechanisms, adjusting the center of gravity to steer and maintain stability. Wingspans of 8 to 11 meters (26.25 to 36.09 feet) and wing surface areas of 12 to 16 square meters (129.17 to 172.22 square feet) provide the necessary lift while maintaining structural integrity.

Hang gliders generate lift through the airfoil profile shape, which creates a pressure differential as air flows over the curved upper surface faster than the lower surface. The lift pressure differential results from Bernoulli's principle, where higher velocity airflow above the wing lowers pressure, while slower airflow beneath maintains higher pressure. Upward force counteracts gravity, enabling sustained flight. Drag opposes forward motion, with drag coefficients ranging from 0.03 to 0.05 at cruising speeds. Newton's third law explains lift generation, as the downward deflection of air produces an equal and opposite upward force. Airflow dynamics guarantee force balance during flight, with lift aerodynamic force offsetting the combined weight of the hang glider and pilot.

Hang glider structural design incorporates lightweight yet strong materials like aluminum alloy or carbon fiber, providing frame structure rigidity and weight efficiency. Wingspan ranges from 8 (26.25 feet) to 11 (36.09 feet) meters, while wing surface area spans 12 (129.17 square feet) to 16 (172.22 square feet) square meters, optimizing lift and minimizing drag. Wing camber enhances lift generation by elevating airflow characteristics. Hang gliders achieve glide ratios between 12:1 and 18:1, reflecting minimized drag and maximized lift. Harness attachment secures the pilot to the frame, distributing forces evenly for stability and safety. Airfoil curvature and wing angle of attack directly influence aerodynamics force balance, with precise adjustments required for optimal performance.

Pilot weight shifting controls hang glider stability and direction by adjusting the center of gravity. Weight-shift control mechanisms allow pilots to shift their body position, altering the glider's attitude and path. Control bar steering provides manual input for roll and pitch adjustments, with the control bar pivot mechanism altering wing aerodynamics. Pilots adapt to thermal heat-induced rising air and ridge lift wind barrier effects by leveraging air currents, wind speed, and direction. Vertical air movement and updraft generation enable altitude gains, sustaining flight over long distances. Pilot balance remains vital during takeoff, cruising, and landing, with harness support providing secure attachment and comfort.

Hang glider design focuses on balancing aerodynamic principles and structural considerations. Material strength ensures durability while maintaining weight efficiency. Airfoil lift coefficient quantifies the efficiency of airflow conversion into lift, with variations in wing surface area and wingspan catering to specific flight conditions. Hang gliders work by optimizing weight-shift control balance adjustment, airfoil profile shape, and wing angle of attack. Hang gliders use advanced materials to achieve a total weight between 20 (44 pounds) and 35 kg (77 pounds), elevating glide efficiency and stability.Pressure distribution and drag friction are minimized to boost performance. Hang gliders stay aloft by combining pilot control input, environmental factors, and precise engineering.

How do gliders take off?

Gliders take off using external launch methods like aerotow, winch launch, or catapult systems. Aerotow involves a powered aircraft pulling the glider into the air using a towline, reaching altitudes of 2,000 (610 meters) to 10,000 (3,048 meters) feet. Winch launch systems use a high-strength cable and a strong winch generating up to 400 horsepower (298 kilowatts) to rapidly accelerate the glider, achieving speeds of 0–60 mph (0–96.56 kilometers per hour) in seconds. Catapult systems deploy stored energy from bungee cords or compressed air to propel the glider forward within distances as short as 1,000 feet (304.8 meters). Glider wings, designed with high lift-to-drag ratios, optimize performance during these launch methods. Runway length varies depending on the method, with aerotow requiring at least 3,000 feet (914.4 meters) and winch launches needing similar space for safety.

Glider wings have long, slender shapes with high lift-to-drag ratios, enabling efficient soaring during and after launch. Aerodynamic features like wing camber and low drag coefficients enhance the glider plane's ability to generate lift while minimizing resistance. These characteristics are pivotal for glider towing dependency, as the glider relies entirely on external forces during takeoff. Runway length varies depending on the launch method, with aerotow requiring at least 3,000 feet (914.4 meters) and winch launch systems needing similar space for safe operation. Runway surface condition and runway type influence safety, as grass or paved surfaces must provide adequate traction and stability for both the glider and towing aircraft.

Weather conditions including wind speed and direction affect glider aerodynamics, with gliders taking off into the wind to maximize lift. Ground support equipment, including towplanes and winches, must meet specific requirements to guarantee successful launches. Aerotow towing aircraft engine thrust ranges from 150 to 300 horsepower, providing sufficient force to pull the glider to altitudes of 2,000 to 10,000 feet (610 to 3,048 meters). Towing stability ensures steady flight paths, reducing the risk of cable breakage or accidents. Winch launch system cable tension achieves rapid acceleration, propelling the glider from 0 to 60 mph (0 to 96.56 kilometers per hour) in seconds. Catapult launch system deployment mechanisms use stored energy from bungee cords or compressed air, accelerating the glider over distances as short as 1,000 feet (304.8 meters).

Pilots focus on operational techniques, maintaining alignment with the towplane during aerotow launches and managing release mechanisms. Engineers emphasize glider wing design and aerodynamics, guaranteeing structures withstand stresses from rapid acceleration. Hobbyists gain a basic understanding of launch methods, recognizing the efficiency and cost implications of each system. Winch launch systems require less infrastructure than aerotow, making them ideal for clubs with limited resources. Catapult launch systems, though less common, provide alternatives in specialized contexts. Glider planes are designed with precision, leveraging advanced materials and engineering principles to maximize performance during takeoff and flight.

How do gliders land?

Gliders land by utilizing precise control, deploying airbrakes to manage descent, and aligning with wind conditions for a smooth touchdown. Glider wings are designed to maximize lift while minimizing drag, allowing efficient control during descent. Pilots deploy airbrakes to increase drag and adjust the descent rate, ranging between 1-2 meters (3.28-6.56 feet) per second. Precise use of the elevator controls pitch and speed, maintaining a stable glide path. Wind conditions, including speed, direction, and gust factors, dictate adjustments to the approach angle for optimal alignment. The flare technique reduces speed just before touchdown, allowing a smooth and controlled landing.

Glider types influence landing techniques due to variations in wing design, weight distribution, and control systems. Manned sailplanes require precise airbrake deployment and a controlled descent rate of 1-2 meters (3.28-6.56 feet) per second. Recreational gliders rely on simpler control mechanisms but maintain similar glide path descent angles. Unmanned radio-controlled gliders depend on pre-programmed adjustments for wind conditions wind speed and wind conditions wind direction. Specialized gliders, like military or experimental models, incorporate advanced flaps and spoilers to manage lift and drag during landing. Pilots adjust their approach based on the specific aerodynamic characteristics of each glider type.

Pilot techniques during landing involve managing airbrakes, flaps, and elevators to control descent rate and pitch. Airbrake’s deployment timing is decisive for producing sufficient drag to stabilize the glider. Flaps adjust lift and drag characteristics while maintaining optimal glide path trajectory. The glider flare technique reduces speed just before touchdown by increasing pitch attitude. Pilots use the rudder to compensate for crosswinds and guarantee proper runway alignment. Flight controls’ responsiveness ensures precise adjustments to ailerons functionality, flap adjustments, and rudder efficiency during the final approach.

Ideal landing conditions include smooth runway surfaces, calm winds, and clear visibility. A runway length of at least 500 meters (1640.42 feet) accommodates most gliders during rollout. Adverse weather, like turbulence or strong winds, requires pilots to adapt quickly to varying wind conditions gust factor. Off-field landings demand consideration of terrain, obstacles, and slope to assure safety. Landing gear deployment mechanism timing and shock absorption reduce impact forces during touchdown. Proper alignment with the wind direction minimizes crosswind effects and ensures a stable approach.

Theoretical and practical aspects of glider landings involve understanding lift, drag, and energy management during descent. Pilots maintain a glide path descent angle of 3 to 5 degrees for a safe approach. During the landing sequence, airbrakes are deployed to control speed and descent rate. The flare technique arrests the descent just before touchdown. Safety protocols dictate that pilots assess runway surface condition and wind conditions before initiating the approach. Gliders using high aspect ratio wings optimize lift while minimizing drag. Weight distribution and pilot skill guarantee stability and control throughout the landing process.

What are key considerations for glider plane design?

Key considerations for glider plane design are outlined below.

- Glider plane design focuses on aerodynamic efficiency: Minimizing drag coefficient to achieve a lift-to-drag ratio of up to 50:1 for superior horizontal travel per unit of altitude loss.

- Wing design geometry in glider plane design impacts drag: High aspect ratios reduce induced drag, with planforms like elliptical, rectangular, swept-forward, or tapered shapes optimizing airflow dynamics.

- Airfoil selection in glider plane design balances lift and drag: Cambered profiles enhance lift generation while maintaining low resistance specialized for specific flight conditions.

- Structural integrity in glider plane design ensures durability: Advanced composites with high strength-to-weight ratios withstand stresses caused by varying airspeed and weight distribution.

- Weight distribution in glider plane design stabilizes flight: Positioning the center of gravity and using water ballast optimizes stability and control during maneuvers.

- Control surfaces in glider plane design guarantee maneuverability: Ailerons, elevators, and rudders are engineered for responsiveness and stability in flight dynamics.

- Tail configuration in glider plane design enhances stability: T-tails or conventional tails streamline airflow and refine fuselage aerodynamics for better glide performance.

- Glide performance metrics in glider plane design measure efficiency: Minimum sink rate and glide ratio evaluate endurance and optimal travel under varying conditions.

- Aspect ratio optimization in glider plane design reduces energy loss: A higher wingspan-to-chord ratio minimizes induced drag, elevating span efficiency during flight.

- Manufacturing constraints in glider plane design balance cost and compliance: Techniques adhere to aviation standards while guaranteeing safety margins and structural integrity validation.

Wing design geometry, including elliptical, rectangular, tapered, or swept-forward planforms, directly impacts induced and profile drag, with high aspect ratios reducing induced drag. A high aspect ratio, calculated as the wingspan divided by the average chord, increases span efficiency and minimizes energy loss during flight. Engineers prioritize airfoil selection to balance lift generation and minimize profile drag, with cambered profiles deflecting airflow downward to create lift while maintaining low resistance. Airflow dynamics and boundary layer behavior directly affect aerodynamics flow, requiring smooth surface transitions to promote laminar flow across the wing design geometry.

What are some notable cargo glider designs?

Notable cargo glider designs are presented below.

- DFS 230 cargo glider design: Known for a payload capacity of up to 1,200 kg (2,645 pounds), including eight fully equipped soldiers, featuring a tubular steel frame and wooden wings for durability in rough terrain operations.

- Waco CG-4A cargo glider design: Transported troops, ammunition, and supplies weighing up to 3,600 kg (7,936 pounds), with a high-wing configuration and upward-swinging nose section for efficient loading and unloading.

- Gotha Go 242 cargo glider design: Accommodated up to 20 fully equipped troops or 3,000 kg (6,614 pounds) of cargo, featuring a loading ramp and robust structural elements for operational flexibility.

- General Aircraft Hamilcar cargo glider design: Carried heavy equipment like Tetrarch light tanks with a payload capacity of 7,000 kg (15,432 pounds), incorporating a spacious cargo bay and a wingspan of 33.5 meters for oversized military assets.

Cargo gliders played roles in military operations by offering unique design features tailored to specific operational needs during World War II. This design emphasized simplicity and durability, guaranteeing reliability during assault missions. The Waco CG-4A wing design incorporated a high-wing configuration with a wingspan of 26 meters (85.3 feet), combining steel tube and fabric construction for optimal aerodynamic performance. Measuring a wingspan of 24.5 meters (80.38 feet), the glider incorporated robust structural elements to support its payload capacity.

What are the parts of a glider?

The parts of a glider include the wing, fuselage, tail, horizontal and vertical stabilizers, cockpit, landing gear, ailerons, airbrakes, and components like tethers and control bars for hang gliders. The fuselage ensures structural integrity while housing the cockpit and distributing weight evenly. Tethers and the control bar enable precise maneuvering in hang gliders through weight shift adjustments.

The wing generates lift through its airfoil shape and aerodynamic design. The curved upper surface of the wing accelerates airflow, creating lower pressure above and higher pressure below, which results in upward lift. Hang gliders feature a high aspect ratio delta wing with a span of 8–11 meters (26.25–36.09 feet). Fuselage structural integrity ensures the glider maintains its shape under various loads. The fuselage plays a vital part in fuselage weight distribution, which directly impacts stability and performance. Lightweight materials like aluminum or carbon fiber are used to construct the frame, providing strength while minimizing weight.

Tail stability is achieved through horizontal and vertical stabilizers. The horizontal stabilizer contributes to pitch stability by balancing lift forces between the main wing and itself. The vertical stabilizer ensures directional stability, maintaining the glider’s orientation during flight. Tail control surfaces include the elevator for pitch control and the rudder for yaw control. The elevator deflection mechanism allows up to ±15° movement, enabling precise adjustments to the glider’s angle of attack. Rudder yaw control involves a steering mechanism connected to the cockpit, allowing up to ±25° movement for effective turning. Conventional gliders rely on these components, while hang gliders depend on wing sweep and pilot weight shift for stability.

Landing gear undercarriage design focuses on shock absorption and functionality. Conventional gliders use fixed or retractable wheels, equipped with rubber or pneumatic systems to absorb impact during landing. Hang gliders lack traditional landing gear, relying on the pilot’s feet and an optional shock-absorbing harness. The cockpit pilot interface includes instrumentation like altimeters, airspeed indicators, and variometers for navigation and control. Hang gliders feature minimal cockpit instrumentation, limited to a variometer and GPS. Conventional gliders have a full panel setup with additional tools like radios for communication.

Airbrake’s drag control manages descent speed and enhances safety during landing. Airbrakes deploy to increase drag, allowing pilots to adjust their descent rate effectively. Ailerons roll control uses a deflection mechanism connected to cockpit controls, enabling up to ±20° movement for precise maneuvering. Hang gliders achieve similar control through weight-shift adjustments facilitated by tethers and the control bar. These components enable pilots to manage pitch and roll by shifting their body position relative to the wing. Both airbrake’s speed management and weight-shift techniques are vital for maintaining control during flight.

What are the characteristics of glider wings?

The characteristics of glider wings include high aspect ratios, smooth airfoil shapes, and positive dihedral angles for stability. Glider wings achieve high aspect ratios, exceeding 20:1, to minimize induced drag and maximize lift-to-drag ratios. Airfoil shapes are carefully designed with moderate camber and thin profiles to optimize laminar flow and reduce drag. Positive dihedral angles, between 5 to 10 degrees, enhance roll stability during flight. Composite materials like carbon fiber provide the necessary strength-to-weight ratio for structural integrity while maintaining lightweight efficiency. Glide ratios in modern gliders reach up to 50:1, enabling long-distance flights with minimal altitude loss.

Glider wing performance relies on physical design and structural features optimized for efficiency. High aspect ratios, exceeding 20:1, reduce induced drag and elevate glide ratios. Wing loading is minimized through lightweight composite materials like carbon fiber, which provide strength-to-weight balance. Glider wings have thin profiles and smooth surfaces to maintain laminar flow, reducing skin friction drag. Airfoil shape incorporates moderate camber and precise curvature to enhance lift while minimizing drag. Glide ratios reach up to 50:1, enabling gliders to travel 50 feet (15.24 meters) horizontally for every foot (0.3048 meters) of altitude lost.

Aerodynamic properties of glider wings are defined by airfoil profiles designed for optimal performance. Moderate camber enhances lift generation without excessive drag, while thin airfoil thickness ensures structural integrity and reduces turbulence. Laminar flow smoothness is achieved through polished surfaces and careful molding, further reducing drag. Aspect ratio span and chord are calculated to maximize efficiency, with high aspect ratios above 20 bettering lift-to-drag ratios. Wing planform taper and minimal sweep reduce tip vortices, contributing to elevated aerodynamic efficiency.

Stability and control in glider wings are influenced by dihedral angle stability and precise construction. Positive dihedral angles between 5 and 10 degrees enhance roll stability, preventing unwanted bank angles during flight. Smooth surfaces and exacting manufacturing processes guarantee consistent aerodynamic performance. Wing structural design stiffness and robustness withstand aerodynamic forces, while lightweight materials maintain efficiency. Composite materials durability and strength provide resistance to fatigue under varying load conditions.

Recreational gliders prioritize simplicity and cost-effectiveness, while competition gliders focus on achieving the highest glide ratios and lift-to-drag ratios. Unmanned gliders integrate advanced technologies for specific missions. Theoretical principles guide modern glider advancement, addressing issues like balancing weight, strength, and aerodynamic efficiency. Glider wings are characterized by high aspect ratios, optimized airfoil shapes, and advanced composite structures to achieve superior performance.

What is the size of a glider plane?

The size of a glider plane varies based on its type, with crewed gliders measuring 27 ft 11 in (8.51 m) length, 53 ft 2 in (16.21 m) wingspan, and competition gliders featuring an 18 m (59 ft 1 in) wingspan. Crewed gliders measure 27 ft 11 in (8.51 m) length, with a wingspan of 53 ft 2 in (16.21 m) and a height of 6 ft 3 in (1.91 m). Competition gliders feature an 18 m (59 ft) wingspan and a wing surface area of 10.5 sq m (113 sq ft). Performance oriented hang gliders range from 22 ft (6.7 m) x 11 ft (3.4 m) to 30 ft (9.1 m) x 15 ft (4.6 m) in size. Aspect ratio defines the relationship between wingspan and average chord length, influencing efficiency. Glider planes optimize aerodynamic performance through high aspect ratios and lightweight materials.

Glider planes exhibit a wide range of dimensions, from foam toy gliders measuring as short as 8 inches (20.32 cm) in length to larger performance-oriented hang gliders reaching up to 30 ft (9.14 m) x 15 ft (4.57 m). Crewed gliders measure 27 ft 11 in (8.51 m) in length, with a wingspan of 53 ft 2 in (16.21 m) and a height of 6 ft 3 in (1.91 m). Competition gliders feature a wingspan of 18 m (59.0551 ft), optimized for efficiency under specific regulatory conditions like the 103.9114 cm (40.9098 in) maximum wingspan for gliders in a 60 cm (23.622 in) box. Performance-oriented hang gliders range between 22 ft (6.71 m) x 11 ft (3.35 m) for smaller models and 30 ft (9.14 m) x 15 ft (4.57 m) for larger ones, emphasizing portability and ease of use.

Wing surface areas vary across glider types, with crewed gliders featuring a wing area of 206.1 sq ft (20.61 sq m) and best-in-class competition gliders having a wing surface area of 10.5 sq m (113.0 sq ft). Aspect ratio defines the relationship between wingspan and average chord length, playing a vital part in aerodynamic efficiency. High-performance gliders like the Eta achieve an aspect ratio of 51.33, maximizing lift while minimizing drag. Glider plane design integrates high aspect ratios to enhance glide performance, with values exceeding 20 being typical for competitive models.

Weight specifications are decisive for operational limits and performance optimization. Crewed gliders have an empty weight of 683 lbs (310 kg) and a max takeoff weight of 1,323 lbs (599 kg), while competition gliders operate within a weight range of 400 kg (882 lbs) to 600 kg (1323 lbs). Lightweight materials contribute to structural strength while minimizing overall mass, guaranteeing efficient flight characteristics. The balance between weight and performance remains a key consideration in glider design.

Performance metrics highlight the efficiency of glider planes, with the Nimeta X achieving a glide ratio of 70:1, indicative of its advanced aerodynamic properties. Glide ratios measure how far a glider can travel horizontally compared to altitude loss, directly influenced by physical dimensions and construction materials. Wing design, including long, narrow configurations and specialized control surfaces, enhances stability and maneuverability. Glider planes rely on precise engineering to optimize lift-to-drag ratios, allowing extended flight durations in varying atmospheric conditions.

What are the different types of gliders?

The different types of gliders are listed below.

- Sailplanes: Advanced aerodynamic design with long, slender wings achieving glide ratios of 30:1 to 60:1, focusing on minimizing drag and utilizing rising air currents like thermals for extended flight durations.

- Hang gliders: Feature flexible delta-shaped frames made from aluminum and Dacron fabric, offering portability and stability through weight-shifting techniques, with a glide ratio of 10:1 to 15:1.

- Paragliders: Use parachute-like canopies made from durable nylon or polyester, guaranteeing high safety with slow descent rates and reserve parachute systems for recreational and competitive flying.

- Motor gliders: Combine traditional glider efficiency with small engines (electric, two-stroke, or four-stroke) for self-launching capabilities and extended flight times after engine shutdown.

- Military gliders: Designed for transporting up to 30 soldiers or heavy equipment during World War II, emphasizing durability in harsh landing conditions and tactical deployment strategies.

- Radio-controlled gliders: Replicate real-world aircraft with maneuverability and aerobatic capabilities, featuring remote control systems and scale models ranging from 1.5 to 5 meters in wingspan.

The different types of gliders include sailplanes, hang gliders, paragliders, motor gliders, military gliders, and radio-controlled gliders. Control surfaces like ailerons, elevators, and rudders enhance precision during flight. Sailplanes glide ratio allows pilots to cover horizontal distances while losing minimal altitude. Hang gliders and paragliders differ in structure and performance but share reliance on rising air for sustained flight. Portability makes hang gliders ideal for recreational use due to their lightweight design. Fabric undergoes rigorous testing to meet tensile strength and UV resistance standards. Motor gliders’ fuel efficiency ensures prolonged soaring after engine shutdown. Military gliders’ capacity allowed them to transport up to 30 soldiers or heavy equipment during World War II. Deployment strategies emphasized stealth and tactical advantage in combat zones. Radio-controlled gliders replicate real-world aircraft with impressive maneuverability and aerobatic capabilities. Maneuverability enables precise handling during aerobatic stunts. Remote control systems provide real-time telemetry data for better piloting. These gliders are popular among hobbyists seeking dynamic flight experiences while maintaining realistic aircraft behavior.

What are balsa gliders?

Balsa gliders are model aircraft made from balsa wood. Balsa wood has a density of 0.1 (0.0062) to 0.2 (0.0123) g/cm³, making it one of the lightest commercially available woods. The low density of balsa wood contributes to the glider's buoyancy in air, aiding in aerodynamic lift. The strength-to-weight ratio of balsa wood is high, guaranteeing structural integrity during flight. Aerodynamic principles like Bernoulli's principle explain the generation of lift in the airfoil design of the wings. Proper dihedral angles enhance stability, allowing predictable flight patterns.

Balsa gliders serve as toy models, educational tools, or competitive aerodynamic designs. Free-gliding models emphasize simplicity and ease of use, making them ideal for beginners. Performance-oriented models incorporate advanced design features to achieve longer flight durations and greater stability. These gliders are constructed in various scales, ranging from small 200 mm (7.87 inches) span designs to larger competition-ready models with wingspans exceeding several meters (several yards). The Jet Fire Balsa Wood Glider achieves glide distances over 25 feet (7.62 meters) when launched correctly. Balsa gliders are popular among hobbyists and professionals alike, offering versatility in both recreational and technical applications.

Aerodynamics efficiency is a pivotal factor, influencing flight duration and scalability. A well-designed balsa glider minimizes drag while maximizing glider lift. Stability during flight depends on precise weight distribution and proper dihedral angles, which enhance glider stability. Larger models mimic full-scale aircraft, providing realism and detailed insights into aerodynamic principles. Flight performance criteria include achieving predictable flight patterns, maintaining structural integrity, and optimizing energy conversion efficiency.

Construction techniques for balsa gliders leverage the unique properties of balsa wood. Balsa wood density ranges from 0.1 (0.0036) to 0.2 (0.0072) g/cm³, allowing lightweightedness while maintaining sufficient strength. Wing shape and dihedral angles are key design elements, directly impacting glider aerodynamics. Airfoil designs generate lift by creating a pressure difference, explained by Bernoulli's principle. Builders carefully select balsa wood types, like A-grain for flexibility and B-grain for stiffness, to optimize performance. Sanding and varnishing reduce aerodynamics drag and protect the structure, providing smooth surfaces and better durability.

The low density of balsa wood reduces overall weight, allowing efficient flight and minimizing altitude loss. Issues in building and flying balsa gliders include precise craftsmanship, careful handling of brittle materials, and technical skills in crafting and assembling components. Resource requirements involve selecting appropriate tools and finishes to maintain structural integrity. Comparisons with synthetic materials highlight the balance balsa wood provides between lightweight construction and high strength-to-weight ratio, making it a preferred choice for model aircraft design.

What are glider drones?

Glider drones are unmanned aerial vehicles that combine the aerodynamic efficiency of gliders with the advanced technology and maneuverability of drones. Glider drones utilize aerodynamic principles to maintain longer flights with less energy. Streamlined designs, like sleek fuselages and high-aspect-ratio wings, optimize their aerodynamic efficiency. Lightweight materials like carbon fiber minimize weight while maintaining structural integrity. Gliding capability allows glider drones to stay aloft using minimal power, aided by rising air currents like thermals. Advanced navigation systems, including GPS and automated flight control algorithms, enable precise tracking and extended mission execution.

Glider drones differ from other drone types like quadcopters and fixed-wing drones. High-aspect-ratio wings and sleek fuselages define glider plane wing design, enabling glider drone aerodynamic efficiency. Lightweight materials like carbon fiber compose the glider drone lightweight structure, providing minimal weight while maintaining structural integrity. Unlike quadcopters, which rely entirely on propulsion systems, glider drones utilize glider drone gliding capability to stay aloft using natural air currents. This design supports extended flight times and reduces reliance on drone propulsion systems.

Applications of glider drones span recreational, commercial, and scientific domains. Environmental monitoring benefits from their ability to cover large areas efficiently, leveraging glider plane gliding performance. Surveillance missions rely on unmanned aerial vehicle (UAV) navigation systems for precise tracking and data collection. Scientific research employs glider drones to study atmospheric conditions, with aerodynamics lift and aerodynamics stability allowing consistent operation in challenging environments. The combination of unmanned aerial vehicle (UAV) automation and remote control system communication enhances mission execution.

Flight performance endurance exceeds hundreds of kilometers when exploiting updrafts and thermals. Glide ratios exceeding 50:1 demonstrate glider drone aerodynamic efficiency. Aerodynamics drag is minimized through streamlined shapes and smooth surfaces, contributing to flight performance range. Stability during turbulent conditions results from advanced flight control systems that maintain drone stability. Maneuverability is achieved through responsive control surfaces, assuring drone mobility across diverse environments. External factors like weather and altitude influence operational effectiveness, requiring real-time adjustments by unmanned aerial vehicle (UAV) automation systems.

Who invented the glider?

Sir George Cayley invented the glider, designing and building the first successful manned glider in 1853. Otto Lilienthal played a pivotal part in advancing glider technology in the late 19th century through numerous tests and experiments.

Sir George Cayley pioneered early glider design principles, establishing foundational knowledge in aerodynamics. George Cayley focused on the relationship between lift and drag, which became vital for aircraft formation. In 1853, George Cayley designed and built a glider capable of carrying a person, marking a milestone in aviation history. His glider design innovations included a fixed wing and tail, components pivotal for stability and control during flight. George Cayley’s work laid the groundwork for future advancements in glider technology.

Otto Lilienthal made over 2,000 experimental flights between 1891 and 1896, refining glider designs through extensive testing. Otto Lilienthal experimental flight techniques involved shifting body weight to control the glider, demonstrating practical methods for maneuverability. Lilienthal was born on May 23, 1848, and became known as the "father of aviation" due to his groundbreaking contributions. Otto Lilienthal glider testing advanced the understanding of wing design and flight dynamics, with his findings published in "Der Vogelflug als Grundlage der Fliegekunst." His use of polar diagrams to analyze lift and drag set standards for modern aerodynamics.

The Wright brothers built upon the research of pioneers like Lilienthal, advancing glider technology further. Wright brothers’ glider advancement included refining aerodynamic principles and bettering flight control systems. Their innovations introduced three-axis control, an important breakthrough in aviation. Wright brothers’ flight innovation led to the creation of the first powered, heavier-than-air aircraft in 1903. Their work demonstrated the feasibility of sustained flight and marked a pivotal moment in aviation progress.

The cumulative influence of George Cayley, Otto Lilienthal, and the Wright brothers defined the evolution of glider technology. George Cayley pioneer efforts established the foundation of aerodynamics, while Otto Lilienthal’s experimental flight achievements inspired generations of aviation innovators. The Wright brothers combined earlier discoveries with their own advancements, achieving milestones that defined modern aviation. Their collective contributions remain integral to the advancement of flight technology.

What are some interesting facts about gliders?

Some interesting facts about gliders are presented below.

- Gliders’ silent operation: Gliders operate without engines, allowing for peaceful and quiet flights ideal for serene landscapes.

- Gliders’ high glide ratio: Gliderscan achieve ratios over 50:1, traveling 50 meters horizontally for every meter of altitude lost.

- Thermal soaring techniques: Gliders use rising warm air currents, or thermals, to gain altitude and extend flight durations.

- Ridge soaring techniques: Gliders utilize wind deflected upward along mountain ridges to maintain constant lift for extended periods.

- Aerodynamics lift-to-drag ratio: High lift-to-drag ratios are central to glider efficiency, enabling longer and more efficient flights.

- Glider design lightweight construction: Lightweight materials like carbon fiber guarantee optimal performance while maintaining structural integrity.

- Wing shape optimization: Advanced wing designs maximize lift and minimize drag, boosting aerodynamic efficiency in gliders.

- Efficient airfoils reduce drag: Airfoil designs in gliders refine glide efficiency and overall maneuverability during flight.

- Thermal updrafts natural lift: Rising warm air provides free energy, enabling gliders to climb higher and glide further effortlessly.

- Constant updrafts along ridges: Wind forced upward over terrain creates reliable lift sources for ridge soaring gliders.

- Glider passive flight: The ability of gliders to soar without engines showcases their reliance on natural forces like thermals and ridge lift.

- History of gliding pioneering innovations: Early aviation experiments laid the foundation for modern advancements in glider technology.

- Record-breaking flights: Refined glider designs have enabled pilots to achieve remarkable distances and durations in flight.

- Glider competitions cross-country issues: Pilots test their skills by soaring vast distances using only natural lift sources.

- Hang gliders recreational flying: Known for simplicity and lightweight design, hang gliders are popular for leisure and sport flying.

Are gliders safer than planes?

Gliders being safer than planes depends on factors like accident statistics, airplane system redundancies, and pilot training skill competency. Glider accidents result in 5-10 fatalities annually among 15,000 active pilots in the U.S., highlighting higher fatality rates compared to general aviation. Airplane safety records demonstrate better performance due to advanced systems and redundancies, guaranteeing safer operations. Pilot training and skill competency emphasizes emergency procedures for glider pilots, addressing unique issues in glider flight stability. Aviation safety risk assessment shows gliders are four times riskier than general aviation, raising concerns about their relative safety. Aircraft design safety features prioritize simplicity in gliders but include robust structures and redundancies in airplanes, impacting overall flight performance maneuverability.

Accident statistics fatality rates reveal glider accidents result in 5-10 fatalities annually among 15,000 active pilots in the U.S., a figure that underscores the higher risk in glider aviation. Airplane safety record demonstrates better performance with advanced airplane system redundancies assuring safer operations during phases like takeoff and landing. Aviation safety risk assessment shows gliders are four times riskier than general aviation, emphasizing the significance of aircraft design safety features. Airplane structural robustness incorporates multiple redundancies to withstand turbulence and adverse weather, which glider design simplicity lacks due to fewer mechanical components.

Operational safety across different conditions highlights glider control issues during adverse weather where aerodynamics stability becomes a liability. Glider flight stability depends heavily on pilot training and skill competency to manage emergencies without engine power, unlike airplane pilots who rely on airplane system redundancies. Emergency response strategies for glider pilots focus on maintaining glide ratio and addressing aerodynamics drag performance. Accident statistics incident trends indicate gliders face higher risks in stall/spin scenarios, linked to deficiencies in glider structural integrity.

Human factors and training requirements stress rigorous pilot training safety protocols for both glider and airplane pilots. Emergency training prepares glider pilots to handle unique problems like winch launch problems and collisions, which are common glider incident scenarios. Regulatory agencies’ certification ensures adherence to aviation safety standards, focusing on glider materials and glider wings to enhance glider flight performance. Aviation safety incident analysis emphasizes the need for high skill competency among glider pilots to mitigate glider fatalities effectively.

Technical design and risk mitigation strategies compare airplane structural robustness with glider design simplicity. Aircraft redundancy systems in airplanes provide extensive backups, minimizing mechanical failure rates and boosting flight performance stability. Glider aviation relies on aerodynamics lift characteristics and efficient glider materials to optimize flight performance glide ratio but faces limitations in flight performance maneuverability. Emergency evacuation protocols in airplanes leverage advanced systems, while glider safety depends on regulatory agencies oversight and compliance with aviation safety standards.