Piston Aircraft: Definition, Difference, Types

Jim Goodrich • • Reading time: 10 min

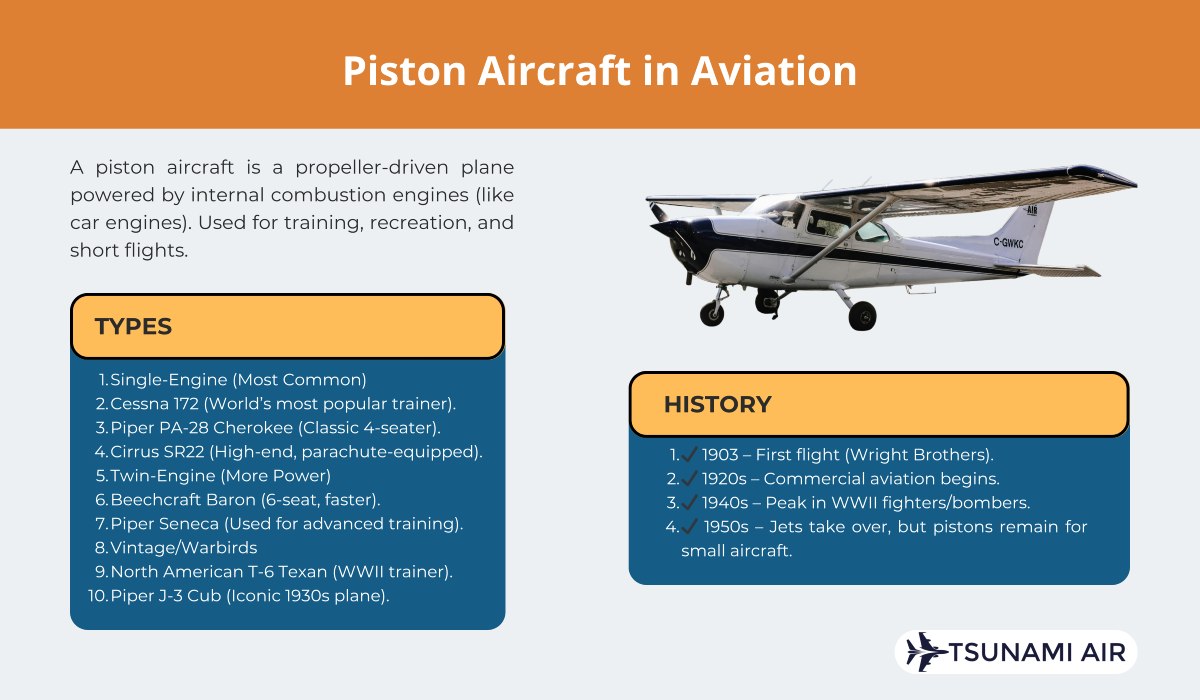

A piston aircraft is an aircraft powered by one or more piston engines driving propellers. The engine of a piston aircraft determines its performance and efficiency. Maintenance of these aircraft focuses on the durability and reliability of their engines. Different models of piston aircraft vary in design and operational capabilities. Fuel consumption directly impacts the operational cost and range of piston aircraft. Types of piston aircraft include single-engine, multi-engine, and specialized variants for specific tasks. Comparison between piston aircraft and other propulsion systems highlights differences in complexity and application. Performance metrics like speed, altitude, and payload capacity depend on the configuration and technology used. Understand the elements of piston aircraft to appreciate their part in aviation.

Piston engines operate through a four-stroke cycle including intake, compression, power, and exhaust. These engines use pistons connected to a crankshaft to convert fuel combustion into rotational energy. The rotational energy drives the propeller to generate thrust. Jet engines differ fundamentally as they utilize a turbine for direct thrust generation. Air enters the jet engine through an inlet and is compressed by a turbine compressor. Compressed air mixes with fuel in the combustion chamber, producing high-speed exhaust gases that expel for thrust. Jet engines achieve efficiency at speeds above 500 mph (804.672 km/h) whereas piston engines excel in low-to-medium speed applications. Maintenance costs for piston engines remain lower due to simpler mechanical systems compared to the intricate turbine systems of jet engines.

Aircraft piston engines classify into types based on cylinder arrangement and cooling methods. Radial engines feature cylinders arranged in a circular pattern providing excellent cooling and a high power-to-weight ratio. Inline engines position cylinders in a straight line reducing aerodynamic drag and making them ideal for smaller aircraft. V-type engines arrange cylinders in two banks at a 60° angle reducing engine length and increasing power output. Flat engines place cylinders on opposite sides of the crankshaft delivering superior balance and reduced vibration. Flat engines dominate modern general aviation with power outputs ranging from 125 hp to 600 hp. Lycoming and Continental produce flat engines with models ranging from 4 to 8 cylinders. Rotary engines, prominent in early aviation, are largely obsolete due to inefficiencies. Spark ignition engines use aviation gasoline while diesel engines operate on the Diesel cycle achieving greater fuel efficiency suitable for extended range or heavy load applications.

What is a piston aircraft?

A piston aircraft is powered by a reciprocating engine, commonly known as a piston engine, which uses pistons connected to a crankshaft to convert fuel combustion into rotational energy for propeller thrust. Piston engines are internal combustion engines that use pistons connected to a common crankshaft. The explosive force of a fuel mixture is converted into rotational energy by the pistons and crankshaft. The rotational motion is transferred to a propeller, which provides thrust for the aircraft. Thrust enables the aircraft to move through the air and take off from the ground. Piston engines are designed with four to six fixed cylinders arranged in a horizontally opposed configuration.

Piston engine combustion involves the conversion of fuel into mechanical energy through a four-stroke process known as the Otto cycle. The reciprocating engine mechanism utilizes pistons moving within cylinders to drive a crankshaft, which transfers rotational energy to the propeller. Aviation gasoline (avgas) serves as the primary fuel, though some engines operate on automotive gasoline. Fuel systems in piston aircraft engines are either carbureted or fuel-injected, with fuel injection boosting performance and efficiency in higher-output models. Propeller aerodynamics play a vital part in thrust generation, with blade design and pitch control directly influencing efficiency and performance.

The airframe of a piston aircraft integrates seamlessly with the piston engine to guarantee optimal operation. Aircraft configuration varies, with single-engine models dominating general aviation usage due to simplicity and cost-effectiveness. Multi-engine configurations provide added safety and performance for specific applications. Aircraft performance is influenced by factors like engine power output, which ranges from 125 hp to 600 hp, and altitude limitations inherent to naturally aspirated or turbocharged engines. Streamlined airframe design minimizes drag, contributing to efficient flight operations. Piston aircraft achieve cruise speeds between 200 and 230 knots, making them suitable for short-distance transportation.

Piston aircraft designs cater to diverse roles within the general aviation market. Small single-engine trainers feature two to four seats and serve flight schools, while larger models accommodate six passengers for touring or cargo transport. Cockpit configurations include basic flight instruments and navigation tools, with modern avionics elevating safety and navigation capabilities. Pilots manage engine cooling, propeller settings, and power adjustments during flight to optimize performance. Reciprocating engine mechanisms require routine maintenance to guarantee reliability and longevity.

Piston aircraft hold a dominant position in the general aviation sector due to affordability and ease of maintenance. General aviation operations rely heavily on piston aircraft for training, recreational flying, and personal transportation. Single-engine piston aircraft are widely used for pilot training, offering low operating costs and straightforward mechanics. Multi-engine models provide redundancy and better performance for advanced flight scenarios. Piston aircraft continue to serve as versatile and efficient options for various flight operations, maintaining their relevance in an evolving aviation sector.

How does a piston engine work?

A piston engine works through a synchronized series of events involving pistons, valves, and fuel combustion. A mixture of fuel and air enters the cylinder as the piston moves downward during the intake stroke. The intake valve opens to allow this mixture into the combustion chamber, creating a low-pressure area. The camshaft controls the timing of the intake valve to optimize fuel-air admission. Compression occurs when the piston moves upward, reducing the cylinder chamber volume to prepare for ignition. The spark plug generates a spark at the precise moment to ignite the compressed mixture.

The reciprocating motion of pistons is vital in transferring power within combustion engines. Pistons move up and down inside the cylinder chamber, driving the four stroke cycle. Connecting rods transmit force from the piston to the crankshaft, converting linear motion into rotational energy. The connecting rod force coupling ensures efficient transfer of energy during each stroke. Crankshaft rotational conversion transforms the piston reciprocating motion into mechanical power through crankshaft mechanical linkage. This process enables the engine to generate rotational energy necessary for powering machinery.

Combustion occurs within the cylinder chamber as the fuel-air mixture ignites. The spark plug generates a spark at precise intervals, achieving spark plug ignition timing. Ignition system timing control ensures optimal spark production for efficient combustion chamber fuel-air combustion. The intake valve opens during the intake stroke, allowing fuel and air to enter the cylinder chamber. Intake valve timing control maximizes air-fuel admission, while exhaust valve timing control regulates the expulsion of exhaust gases. Exhaust expulsion occurs during the final stroke, completing the four stroke cycle.

The ignition system produces sparks required for combustion, synchronizing with the camshaft for precise operation. Fuel injection system ensures accurate amounts of fuel are introduced into the cylinder. Fuel injection system atomization enhances mixing of fuel and air, refining combustion efficiency. The camshaft controls valve actuation, guaranteeing synchronized opening and closing of the intake and exhaust valves. Camshaft timing synchronization aligns valve movements with piston motion, optimizing performance throughout the stroke cycle.

Support systems maintain engine efficiency and longevity. The lubrication system reduces friction between moving parts, distributing oil evenly throughout. Friction reduction prevents wear and overheating. The cooling system regulates engine temperature by dissipating heat through cooling system heat dissipation. Cooling system’s temperature regulation prevents damage caused by excessive heat. Engine block’s structural support houses the cylinders, providing stability for cylinder combustion containment. These systems work together to guarantee reliable operation of internal combustion engines.

What is the difference between a piston engine and a jet engine?

The difference between a piston engine and a jet engine is explained in the table below.

Criteria | Piston Engine | Jet Engine |

Basic Operation | Uses cylinders and a crankshaft to convert combustion energy into mechanical drive for a propeller. | Utilizes a turbine to compress air, mix with fuel, and expel high-speed exhaust gases to produce thrust. |

Cycle Type | Four-stroke cycle: intake, compression, power, exhaust. | Continuous combustion cycle in the combustion chamber. |

Fuel Consumption | 12-20 gallons (45.4-75.7 liters) per hour. | As little as 2 gallons (7.6 liters) per hour under optimal conditions. |

Efficiency at Speeds | Best performance at low-to-medium speeds. Loses performance at higher velocities. | Reaches efficiency at speeds above 500 mph (804.672 km/h). |

Mechanical Components | Cylinders, pistons, crankshaft, fuel pumps, carburetors, or fuel injectors. Propeller blade design is critical. | Turbine compressor, combustion chamber, turbine blades, nozzle. |

Energy Conversion | Converts linear piston motion into rotational motion via crankshaft to drive a propeller. | Compresses air, ignites fuel-air mixture, and expels exhaust gases at high speed for thrust. |

Maintenance Costs | Lower due to simpler design. Regular upkeep includes oil changes and tune-ups. | Higher due to complex turbine systems. Requires specialized expertise for turbine maintenance. |

Rotational Speed | Operates at lower speeds relative to jet engines. | Turbine blades operate at speeds exceeding 10,000 RPM. |

Applications | Ideal for low-to-medium speed applications, such as general aviation and small aircraft. | Suitable for high-speed applications, including commercial airliners and military jets. |

Piston engines rely on piston engine cylinders to execute the combustion cycle. Propeller pitch determines the angle of attack, with adjustable pitch elevating performance across varying flight conditions. Air enters the jet engine through an inlet, where it is compressed by the turbine compressor before entering the jet engine combustion chamber. These gases drive the jet engine turbine, which powers the compressor and fan blades. Aircraft propulsion system engine integration ensures optimal airflow and pressure increase within the engine. Piston engines feature simpler designs, resulting in lower maintenance costs. Regular upkeep includes oil changes and engine tune-ups to guarantee longevity. Aircraft propulsion system fuel efficiency highlights the trade-off between operational costs and performance capabilities. Piston engines require frequent attention due to their mechanical drive systems, while jet engines demand specialized expertise for turbine and combustion chamber maintenance.

What are the types of aircraft piston engines?

The types of aircraft piston engines are outlined below.

- Radial aircraft piston engines: Radial engines feature cylinders arranged in a circular pattern around the crankshaft, providing cooling and a high power-to-weight ratio, historically used in early aviation.

- Inline aircraft piston engines: Inline engines position cylinders in a straight line, offering compactness and reduced drag, making them ideal for smaller aircraft with limited engine space.

- V-type aircraft piston engines: V-type engines arrange cylinders in two banks at a 60° angle, reducing length while increasing power output, commonly used in World War II aircraft.

- Flat aircraft piston engines: Flat (horizontally opposed) engines place cylinders on opposite sides of the crankshaft, delivering superior balance and low vibration, widely adopted in modern general aviation.

- Rotary aircraft piston engines: Rotary engines, with rotating crankcases and stationary cylinders, were prominent in early aviation but are now largely obsolete due to inefficiencies.

- Spark ignition aircraft piston engines: Spark ignition engines use aviation gasoline as fuel, with spark plugs igniting the air-fuel mixture during the compression stroke, governed by the Otto cycle.

- Diesel aircraft piston engines: Diesel (compression ignition) engines operate on the Diesel cycle, utilizing higher compression ratios to ignite the fuel-air mixture without spark plugs, achieving greater fuel efficiency.

Flat engines dominate modern general aviation due to their aerodynamic advantages, reliability, and efficiency, with manufacturers like Lycoming and Continental producing models ranging from 4 to 8 cylinders and power outputs between 125 hp and 600 hp.