Seaplane: Definition, Function, Types, Size, History

Jim Goodrich • • Reading time: 23 min

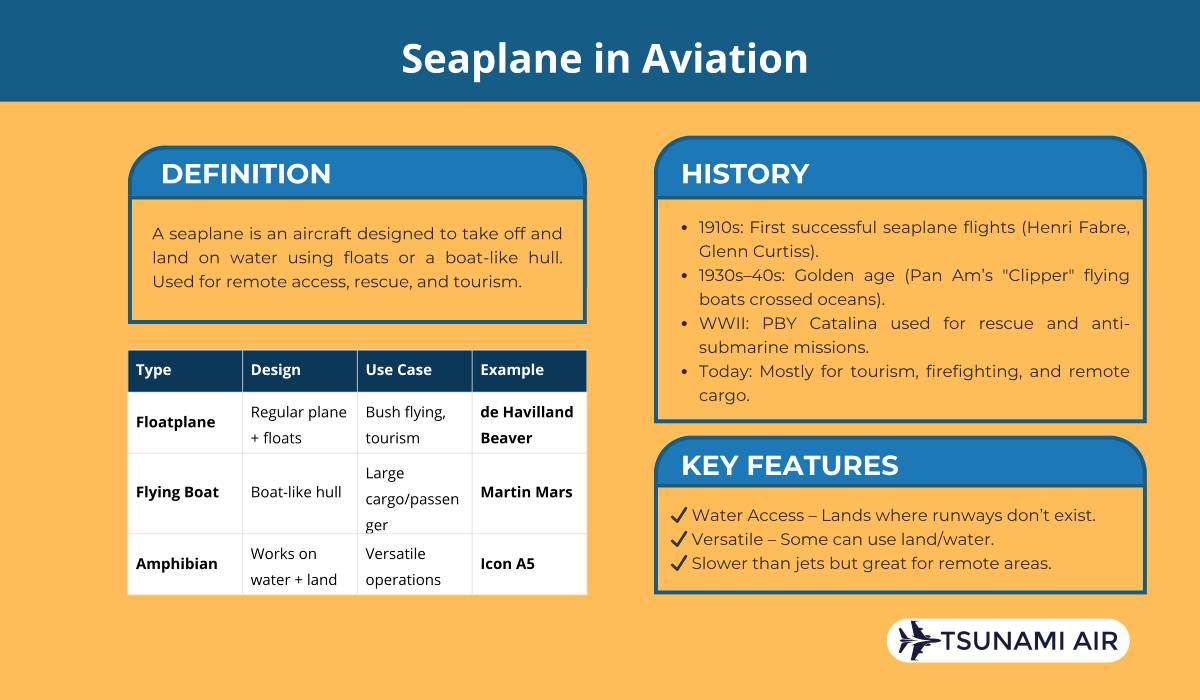

A seaplane is an aircraft designed to take off from and land on water. Seaplanes operate using a hull or floats for buoyancy and stability on the water surface. The history of seaplanes reflects advancements in aviation technology. Seaplanes are classified into distinct types based on their design and functionality. Learn about seaplane takeoff mechanisms, types, historical advancement, and hull structure.

Seaplanes achieve varying altitudes depending on their design and purpose. Small unpressurized seaplanes cruise at 4,000 feet (1,219 meters) while turboprop models reach up to 15,000 feet (4,572 meters). High-performance seaplanes attain altitudes of 20,000 feet (6,096 meters) in rare cases. During water operations, seaplanes fly at 1,000 feet (304.8 meters) for takeoffs and landings.

Seaplanes fall into three main categories: flying boats, floatplanes, and amphibious seaplanes. Flying boats use a boat-like hull for buoyancy and water interactions. Amphibious seaplanes integrate retractable wheels within floats, enabling operations on both land and water. Each type serves specific roles in transportation, tourism, and military applications.

Seaplane lengths range from 32.8 feet (10 meters) to 12.67 meters (41.6 feet), with wingspans between 14.9 meters (48.9 feet) and 16 meters (52.5 feet). Heights vary from 10.4 feet (3.17 meters) to 5.3 meters (17.39 feet). Smaller seaplanes measure 10.7 meters (35.1 feet) in length with a wingspan of 14.9 meters (48.9 feet) and a height of 3 meters (9.8 feet). Floats on seaplanes measure 5.36 meters (17.6 feet) in length, while amphibian floats extend to 5.46 meters (17.9 feet).

Henri Fabre's Hydravion achieved the first powered seaplane flight in 1910. Glenn Curtiss advanced the design with the Curtiss Model E Flying Boat, featuring a covered hull for better stability. The USS NC-4 completed the first transatlantic flight in 1919, piloted by Lt. Cmdr. Albert C. Read. Seaplanes played vital roles during World War I and World War II, performing reconnaissance, patrol, and transport missions. Post-war developments introduced corrosion-resistant materials and boosted engine performance. Modern innovations continue to expand seaplane capabilities for civilian and military uses.

What is a seaplane?

A seaplane is a fixed-wing aircraft designed to take off from and land on water, using floats or a boat-like hull for support. The design of the seaplane enables takeoffs and landings where traditional runways or airfields are unavailable. Seaplanes are divided into two main categories: float planes with pontoons and flying boats with boat-like fuselages. Floatplanes are landplanes modified with floats instead of wheels, while flying boats use their fuselage for water landings. Both types operate on seas or other bodies of water under different conditions.

Flying boats feature a hull designed for water buoyancy, enabling seamless landings and takeoffs on water surfaces. The flying boat hull integrates hydrodynamic efficiency to reduce drag while moving across water. Floatplanes rely on pontoons or floats instead of wheels, providing the necessary stability and floatplane buoyancy for water-based operations. Amphibious aircraft versatility allows certain models to operate on both land and water, utilizing landing gear with retractable wheels within the floats. Seaplanes generate lift by leveraging water density during takeoff, allowing efficient transitions from water to air.

Seaplanes are integral to marine aviation fleets, performing roles like reconnaissance, rescue missions, and cargo transport. Structural adaptations like robust airframes and corrosion-resistant materials enhance durability in saltwater environments. The history of seaplane innovation highlights milestones including the NC-4's transatlantic crossing in 1919 and the Soviet ANT-4's journey from Moscow to New York in 1929. Accidents in early seaplane operations defined safety standards, emphasizing rigorous testing and pilot training. Seaplane pilots undergo specialized instruction to master techniques for handling unique conditions like wave action and water surface interactions.

Operational dynamics involve precise coordination of aerodynamics and engine performance specialized for water operations. Aircraft engines balance power output with fuel efficiency to guarantee consistent thrust in challenging weather. Seaplane cost factors vary, with basic models starting at $50,000 and larger commercial seaplanes exceeding $1 million. Companies involved in seaplane sales cater to diverse markets, including tourism operators and remote communities. Training programs provided by certified seaplane instructors equip pilots with skills for safe seaplane takeoff and landing procedures. Naval operations historically relied on seaplanes for reconnaissance and maritime rescue missions.

How high do seaplanes fly?

Seaplanes fly as high as 20,000 feet (6,096 meters) in rare cases for high-performance models, but operate at lower altitudes like 4,000 feet (1,219 meters) for small unpressurized seaplanes or 8,000 feet (2,438 meters) over mountainous terrain. Small unpressurized seaplanes cruise at 4,000 feet (1,219 meters). Turboprop seaplanes reach altitudes of up to 15,000 feet (4,572 meters) under optimal conditions. Seaplanes operate at 1,000 feet (304.8 meters) during water landing or takeoff operations. Low-altitude flights at 500 feet (152.4 meters) are common for sightseeing or coastal routes.

How does a seaplane take off?

A seaplane takeoff involves transitioning through phases where water lift and wing lift play vital roles. Seaplanes are equipped with floats or a hull designed to provide buoyancy and stability during water operations. The planing surface of the floats reduces drag as the seaplane accelerates through phases like displacement, hump, and planing. Water conditions affect takeoff, with smooth water reducing resistance and rough water requiring advanced techniques for efficient lift-off. Hydrodynamic lift supports the seaplane's weight until achieving planing speed, ranging from 30 to 40 knots depending on the design. Aerodynamic lift becomes dominant as the pilot applies gentle back elevator pressure to transition the aircraft into the air.

Smooth water reduces drag, allowing for efficient acceleration through the displacement, hump, and planing phases. Rough water increases resistance, requiring pilots to apply advanced techniques like adjusting throttle settings and maintaining precise elevator control. Wind speed and direction affect performance, with headwinds aiding lift generation and tailwinds increasing takeoff distance. Pilots align the seaplane into the wind during pre-takeoff preparation, retracting water rudders to minimize directional control issues. Seaplane design configurations incorporate floats or a hull with hydrodynamic shapes that optimize buoyancy and stability during varying water conditions.

Hydrodynamic lift dominates during the initial phases of takeoff, aiding the seaplane’s weight as it transitions through displacement, hump, and planing stages. The floats or hull feature a planing surface that reduces drag by creating hydrodynamic flow, enabling the seaplane to achieve planing speed ranging from 30 to 40 knots. Aerodynamic lift wing lift becomes important during the lift-off phase when gentle back elevator pressure lifts the nose, transferring support from the floats to the wings. Engine power output generates thrust propulsive force through the propeller propulsion mechanism, overcoming water resistance in the hump phase and sustaining acceleration during planing. Floats’ buoyancy ensures stability, while the hull planing surface minimizes drag during high-speed transitions.

Seaplane design variations impact the takeoff process depending on whether the aircraft is a floatplane or an amphibious seaplane. Floatplanes rely solely on external floats for buoyancy and stability, whereas amphibious seaplanes integrate retractable landing gear with a hull for versatility. Weight distribution differs between these designs, affecting engine power requirements and acceleration efficiency. Amphibious seaplanes require higher engine power output due to increased structural weight. Engineering features like optimized planing surfaces and strategic engine placement enhance hydrodynamic lift during the hump and planing phases. Achieving planing speed depends on the specific design configuration, influencing overall takeoff performance.

Pilots follow precise steps during the seaplane taking procedure, beginning with aligning into the wind and retracting water rudders. Applying full throttle accelerates the seaplane through the displacement phase, where water resistance is highest. During the hump phase, careful control prevents excessive drag as the seaplane pushes through increased resistance. Maintaining a steady step attitude during the planing phase reduces porpoising risks while guaranteeing efficient hydrodynamic lift. Engineers focus on optimizing float design and structural integrity to handle dynamic loads during takeoff. Technical considerations include assuring the hull hydrodynamic shape supports smooth transitions across all phases while minimizing drag forces acting on the seaplane.

Can you land a seaplane anywhere?

No, you cannot land a seaplane anywhere. Landing depends on environmental conditions, water body size, regulatory restrictions, and seaplane capabilities. Seaplanes require a minimum water surface width of 400 feet (121.92 meters) for safe operations in certain regions like Illinois. Water depth must exceed 50 cm (19.685 inches) to provide sufficient clearance for the hull or floats. Wave height tolerance varies based on seaplane design, with most models handling waves up to 12 inches (30.48 centimeters) safely. Strong water currents over 5 knots create instability during landing and taxiing. Aviation regulations mandate adherence to U.S. Coast Guard rules and local ordinances for legal landings.

Seaplane water landing capability depends on the size and depth of water bodies, with minimum requirements guaranteeing safe operations. A seaplane lake must provide an obstruction-free surface, mandated at 400 feet (121.92 meters) wide in regions like Illinois. Water depth exceeding 50 cm (19.69 inches) ensures sufficient clearance for the seaplane hull or floats. Aviation regulations compliance includes adherence to U.S. Coast Guard rules and local ordinances, which impose additional restrictions or require specific permits for landing. Pilot judgment and risk assessment evaluates environmental conditions including visibility, tide patterns, and potential hazards before selecting a landing site.

Strong water currents over 5 knots destabilize seaplanes during landing and taxiing. Wind affects control, necessitating adjustments to approach speed and direction. Wave height tolerance varies by seaplane design, with most models handling waves up to 12 inches (30.48 centimeters) safely. Water body obstructions like rocks, logs, or debris pose risks to the seaplane hull. Seaplane pilots assess water body surface conditions, including glassy water or choppy waves, to determine optimal landing techniques.

Pilot judgment and experience are decisive in managing seaplane operations. Flight safety risk management involves continuous monitoring of environmental conditions including visibility, tide, and wind. Training equips pilots to handle unique issues posed by rough water or adverse weather conditions. Seaplane hull design provides buoyancy and stability, allowing operations in diverse water bodies of varying sizes but requiring careful evaluation of conditions. Pilots follow flight safety protocols, maintain certifications, and adhere to regulatory restrictions to guarantee safe and legal landings.

Why do airline companies find seaplanes useful?

Airline companies find seaplanes useful for operational efficiency, market expansion, and service diversification. Seaplanes eliminate the need for traditional airport infrastructure, reducing costs associated with runway maintenance and advancement. Remote islands and coastal communities gain better connectivity, addressing problems of isolation and accessibility. Water aerodromes with minimal docking facilities enable operations in diverse environments, including open oceans and small lakes. Emergency response and medical evacuation services benefit from seaplanes' rapid deployment capabilities. Tourist destinations experience increased attraction due to scenic flights and unique travel experiences.

Seaplanes allow access to remote or underserved areas without reliance on traditional airport infrastructure, elevating airline companies’ market expansion. Coastal communities and islands gain better connectivity through water aerodromes with minimal docking facilities, addressing coastal communities’ accessibility and remote islands’ isolation. Tourist destinations experience heightened attraction due to scenic flights and unique travel experiences, contributing to tourism. Seaplanes operate in diverse environments, including open oceans and small lakes, showcasing their amphibious capability and versatility.

Airline companies achieve cost efficiency by reducing expenses associated with runway maintenance and land acquisition. Water-based operations lower infrastructure costs while maintaining connectivity. Emergency response benefits from seaplanes’ flexibility, enabling faster deployment in medical evacuations and disaster relief scenarios. Seaplanes require fewer resources for docking compared to traditional airports, optimizing water aerodromes infrastructure.

Seaplane operations demand specialized training for seaplane pilots and adherence to unique maintenance requirements. Availability of suitable water landing sites varies across regions, influencing seaplane flight effectiveness. Regulatory frameworks favor seaplanes in environments where land-based infrastructure is impractical, maintaining compliance with safety standards. Seaplanes contribute to airline companies’ service diversification by offering niche services unavailable through conventional aircraft.

Comparative analysis reveals seaplanes as cost-effective solutions for specific geographic and market conditions. Airline companies utilize seaplanes to supplement traditional aircraft in targeted markets, boosting operational efficiency. Remote islands’ connectivity improves through direct point-to-point travel, reducing travel time and boosting economic growth. Coastal communities’ economic growth accelerates as seaplanes link markets and services, fostering regional growth.

What are the types of seaplanes?

The types of seaplanes are given in the table below.

Type of Seaplane | Description | Key Features | Examples/Market Information |

Flying Boats | Feature a boat-like hull for buoyancy. | - Hydrodynamic and watertight flying boat hulls. - Accommodate crew, passengers, cargo during long-range flights. - Amphibious variants include retractable landing gear. | - Historical examples: Consolidated PBY Catalina, Chetverikov MDR-6. - Critical in military surveillance and remote area access. |

Floatplanes | Rely on pontoons beneath the fuselage. | - Two main floats or single central float with outriggers. - Lightweight, watertight materials for optimal water performance. - Some models integrate amphibious seaplane landing gear. | - Example: de Havilland Canada DHC-2 Beaver. - Used in private, commercial, and bush flying sectors. - Serve tourism, emergency services, and remote transport. |

Amphibious Seaplanes | Combine features of flying boats and floatplanes. | - Retractable amphibious seaplane landing gear. - Landing gear retracts into hull or floats. - Eliminate the need for separate runways. | - Excel in dual operations (land and water). - Support roles in emergency services and remote access. - Growing demand in regions with limited infrastructure. |

What is a twin-engine seaplane?

A twin-engine seaplane is a powered fixed-wing aircraft equipped with two engines, designed to take off and land on water using floats or pontoons, offering increased performance, safety, and versatility for remote area access and specialized missions. Two engines provide redundancy, allowing continued flight if one engine fails. Floats or pontoons support the aircraft during water operations, enabling access to lakes, rivers, and coastal regions. Twin-engine seaplanes achieve faster cruise speeds and better takeoff performance, making them ideal for STOL operations. Lycoming engines power these aircraft, producing up to 300 hp each for a total of 600 hp. Engines mounted above the fuselage in a tractor configuration enhance stability and control during water landings and takeoffs.

The twin-engine configuration in seaplanes involves two engines mounted either on the wings or above the fuselage, providing balanced thrust and stability during water operations. Redundancy achieved through this setup ensures continued flight even if one engine fails, boosting safety. Each Lycoming O-435 engine in aircraft like the Grumman G-44 Widgeon produces 190 horsepower, totaling 380 hp, which directly supports engine power output and improves float stability during water takeoff. Float hydrodynamics play a vital part in water operability, as the design minimizes drag while maximizing buoyancy. Seaplane float design incorporates features like spray reduction and even buoyancy to maintain stability and prevent capsizing. Amphibious models further expand versatility by incorporating retractable wheels, enabling operations in both aquatic and terrestrial environments.

Twin-engine seaplanes achieve superior performance due to better power distribution, allowing for quicker acceleration and shorter takeoff distances on water. The increased engine thrust contributes to higher cruise speeds and better climb rates, making these aircraft ideal for STOL operations. Aircraft aerodynamics are influenced by the presence of floats, which create additional drag, but the twin-engine configuration mitigates this by delivering sufficient power output. Viking Twin Otter models, equipped with two PT6A-34 engines flat-rated to 620 horsepower each, demonstrate optimized engine fuel efficiency while maintaining robust airframe durability. Modern advancements in engine technology focus on reducing fuel consumption without compromising thrust or overall flight performance.

The combination of twin-engine seaplane water operability and amphibious capability makes these aircraft suitable for diverse missions, from recreational flying to commercial operations in remote areas. Floats designed for low water resistance and high buoyancy guarantee efficient water takeoff, while precise control over speed and pitch enhances maneuverability. The robust construction of the aircraft airframe supports the stresses of both water and air environments, providing reliability during extended operations. Twin-engine configuration redundancy remains a cornerstone of safety in challenging conditions over large bodies of water or turbulent seas.

What is a cargo seaplane?

A cargo seaplane is a powered aircraft designed to carry large volumes of cargo, often featuring specialized systems and the ability to take off and land on water. Cargo seaplanes maximize cargo capacity by incorporating large internal volumes and specialized cargo carriage systems. Wings are designed with the widest wingspan possible to support heavy payloads during takeoff and landing on water. Operations focus on military missions, disaster response, and civilian transport in areas lacking traditional airstrips. Floatplanes use pontoons for water support while flying boats integrate hull designs for stability. Organizations like DARPA explore experimental designs to meet future kiloton-scale transport needs.

Amphibious aircraft’s versatility allows cargo seaplanes to operate efficiently on both water and land. Floats provide buoyancy through multiple watertight compartments, guaranteeing stability during water operations. Flying boats incorporate hull designs that act as the fuselage, boosting water landing stability. Aircraft aerodynamics minimize drag while wide wingspans support heavy payloads during water takeoff and landing. Amphibious capability ensures access to remote areas lacking traditional infrastructure.

Cargo transportation logistics benefit from specialized systems in cargo seaplanes. Freighters feature large internal cargo holds designed to maximize space efficiency for secure stowage. Loading and unloading processes are streamlined to handle various types of cargo, including military equipment, disaster relief supplies, and civilian goods. Amphibious aircraft are vital in transporting materials to regions with limited or no airstrips, allowing reliable delivery in challenging environments.

Aircraft propulsion systems in cargo seaplanes are optimized for efficient water-based operations. High-torque propellers overcome drag and resistance during water takeoffs and landings. Spray rails incorporated into the design reduce water spray impacting propellers, allowing smooth performance. Water landing buoyancy is achieved through robust floatation systems that support at least 180% of the aircraft's takeoff weight, meeting FAA regulations.

Cargo seaplane payload capacity varies based on size and design, with larger models capable of transporting several tons of freight. Experimental designs by organizations like DARPA aim to enhance functionality for kiloton-scale transport needs. Seaplane water takeoff requires careful planning to achieve lift-off within limited distances. Amphibious aircraft capability provides flexible and efficient solutions for modern cargo transportation demands.

What is a biplane seaplane?

A biplane seaplane is a type of aircraft that combines two sets of stacked wings, characteristic of a biplane, with the water-based operational functionality of a seaplane. Biplane seaplanes incorporate two sets of wings stacked vertically, generating increased lift and stability required for agile flight. Pontoons or floats replace traditional landing gear, enabling water-based takeoffs and landings on lakes and rivers. Modern designs integrate advanced propulsion systems, boosting versatility while retaining the biplane's hallmark agility. Aerodynamic interference between the wings reduces efficiency but adds maneuverability, making these aircraft ideal for aerobatic displays. Pilots value biplane seaplanes for their compact design, allowing access to smaller water bodies with limited infrastructure.

The biplane dual wing configuration generates a wing aerodynamic profile that enhances lift at lower speeds, vital for biplane seaplane aircraft performance. Each wing contributes to wing lift generation, yet the total lift remains less than double that of a single wing, reducing the lift coefficient by 10 to 15% compared to monoplanes. Cabane struts support the upper wings while lower wings attach directly to the fuselage, providing wing structural support. The design introduces interference drag, impacting aircraft aerodynamics, but interplane struts and bracing wires maintain stability and rigidity despite increased drag. Biplane structural bracing remains vital for handling stresses during air and water operations.

Seaplane floatation systems rely on pontoons or floats designed with a step to minimize drag during seaplane water takeoff. Float buoyancy supports up to 180% of the aircraft's takeoff weight, providing stability and safety. The seaplane hull design incorporates watertight compartments to maintain buoyancy and handle stresses from water impacts. Float water displacement plays a vital part in hydrodynamic performance, with beam, chine, and dead rise optimizing water-based functionality. A robust float attachment mechanism connects the floats to the aircraft fuselage, absorbing water forces and maintaining stability during operations.

Modern biplane models integrate advanced aircraft propulsion systems to counter drag from the biplane configuration and floats. Propeller-driven engines suit low-speed operations typical of water takeoffs and landings, boosting versatility. The streamlined hull design reduces water resistance, elevating efficiency during seaplane water takeoff and landing phases. Structural reinforcements in the aircraft fuselage design withstand stresses from both air and water environments. Specific biplane models balance aerobatic performance with access to remote water bodies, making them ideal for specialized missions.

Biplane aircraft excel in aerobatic displays due to their stability and responsiveness, hallmarks of famous biplane designs. Shorter wingspans provide advantages in confined environments, enabling operations on smaller water bodies with limited infrastructure. Notable biplane models combine the benefits of biplane wing stacking with efficient floatation systems, addressing issues of water-based flight. Pilots undergo specialized training to manage the aerodynamic characteristics of biplanes and the demands of water operations, guaranteeing safe and effective performance.

What is the size of a seaplane?

The size of a seaplane is given in the table below.

Seaplane Model | Length (m / ft) | Wingspan (m / ft) | Height (m / ft) | Float Length (m / ft) |

General Range | 10 - 12.67 m (32.8 - 41.6) | 14.9 - 16 m (48.9 - 52.5) | 3.15 - 5.3 m (10.3 - 17.4) | 5.36 - 5.46 m (17.6 - 17.9) |

Cessna Grand Caravan EX (Seaplane) | 12.67 m (41.57 ft) | 15.87 m (52.07 ft) | 5.31 m (17.42 ft) | Amphibian: 5.46 m (17.91 ft) |

Selina Amphibious Aircraft | 10.7 m (35.1 ft) | 14.9 m (48.9 ft) | 3 m (9.8 ft) | Seaplane: 5.36 m (17.59 ft) |

What is inside a seaplane?

The inside of a seaplane includes cockpit instruments, fuel tanks, passenger seating, cargo compartments, safety equipment, and navigation systems. Cockpit instruments include altimeters, compasses, airspeed indicators, and navigation displays. Fuel tanks are located in the wings or fuselage, providing a safe and efficient fuel storage system. Passenger seating features adjustable seats with safety belts, designed for comfort and safety. Cargo compartments offer storage space with cargo securing systems to guarantee safe transport. Safety equipment includes life jackets, emergency rafts, a first aid kit, and a fire extinguisher. Navigation systems feature GPS modules, radar, altimeters, and compasses for precise location and route guidance. Control surfaces like ailerons, elevators, and rudder manage roll, pitch, and yaw. Hydraulic systems use pumps, reservoirs, and actuators to operate landing gear and other functions. Electrical systems distribute power through wiring and power distribution panels, powered by a reliable battery.

Cockpit instruments include altimeters, airspeed indicators, heading indicators, and navigation displays. Cockpit control panels house controls for flight including throttle, propeller pitch, and flap controls. Cockpit seats are designed for the pilot and sometimes a co-pilot or passengers. Seaplanes have avionics communication systems which include radio transceivers for voice communication with air traffic control and other aircraft. Avionics display screens provide digital displays for flight data, navigation, and engine performance. Navigation systems feature GPS modules offering precise location and velocity data. Radar is used for detecting weather and other aircraft while the altimeter measures altitude above sea level. The compass provides directional information needed for navigation.

Seaplanes have engines that can range from reciprocating to turbine types. Engine pistons convert the explosive force of fuel into mechanical energy. The engine propeller converts mechanical energy into thrust and is a constant-speed propeller for efficiency across different flight regimes. The engine ignition system ensures reliable start and operation using spark plugs or fuel injection systems. Fuel tanks are located in the wings or fuselage and provide a balance between weight and fuel capacity. The fuel gauge monitors fuel levels and is vital for flight planning. Fuel storage capacity ranges from 30 (113.55 liters) to 100 (378.54 liters) gallons depending on the seaplane model.

Control surfaces include ailerons, elevators, and rudder which manage roll, pitch, and yaw. Servo mechanisms assist in automating control surface movements in some aircraft. Cable controls connect cockpit controls to the control surfaces allowing precise maneuverability. Hydraulic systems feature hydraulic pumps pressurizing fluid stored in reservoirs. Actuators execute hydraulic commands like extending landing gear or operating flaps. Electrical systems distribute power through wiring connected to a power distribution panel. The battery powers pivotal systems when the engine is off.

Passenger cabin seating accommodates passengers with adjustable seats and safety belts providing comfort and security. Passenger cabin interior layout is designed for efficiency and accessibility. Cargo compartment storage space varies by aircraft type and is equipped with cargo securing systems to guarantee safe transport. The loading hatch facilitates easy access for loading and unloading cargo. Safety equipment includes life jackets mandatory for water operations and emergency rafts providing flotation in case of ditching. A first aid kit supplies basic medical tools while a fire extinguisher is available for emergency fire suppression.

What is the history of the seaplane?

The history of the seaplane is outlined below.

- Henri Fabre's seaplane innovation: Designed and flew the first practical seaplane, the Fabre Hydravion, in 1910, marking a milestone in aviation history with its biplane configuration and floating hull.

- Glenn Curtiss's seaplane advancements: Developed the Curtiss Model E Flying Boat in 1912, incorporating a covered hull and "step" design for refined buoyancy and stability.

- The Fabre Hydravion seaplane prototype: Achieved the first successful powered seaplane flight in 1910, demonstrating the feasibility of water-based aviation operations.

- Curtiss seaplane military applications: Seaplanes were extensively used during World War I for reconnaissance, anti-submarine patrols, and bombing missions.

- USS NC-4 seaplane transatlantic flight: Completed the first transatlantic flight in 1919, piloted by Lt. Albert C. Read, showcasing seaplane capabilities in long-range missions.

- World War II seaplane evolution: Seaplanes played vital roles in amphibious assaults, reconnaissance, transport, and rescue operations, particularly in the Pacific Theater.

- Technological advancements in seaplanes: Post-war developments included refined materials, engines, and designs specialized for diverse operational conditions.

- Seaplane bases worldwide: Established to support both military and civilian applications, boosting operational efficiency for seaplane missions.

- Seaplane pilot training: Specialized training programs were developed to address unique issues , including takeoff and landing practices on water surfaces.

- Modern seaplane innovations: Advanced materials and technologies reflect the dual influence of military and civilian uses, guaranteeing seaplanes remain indispensable tools in aviation.

How much does a float plane cost?

The cost of a float plane depends on factors like whether it is a basic recreational model, an amphibious-equipped version, or a high-end multi-engine seaplane. Basic single-engine recreational seaplanes start at $30,000 for used models. A float plane with an empty weight of 800 lbs (362.87 kg) costs around $44,000. Amphibious-equipped models reach prices of $350,000. High-end multi-engine seaplanes cost up to $3,000,000. Adding floats to an existing aircraft requires an investment of $20,000 to $50,000.

Used single-engine recreational seaplanes provide an affordable entry point into float plane ownership, starting at $30,000 for used models. A basic float plane with an empty weight of 800 lbs (363 kg) costs $44,000, making it suitable for recreational purposes. Float-equipped R172K models in good condition reach prices up to $90,000, offering a balance of performance and cost for small-scale operations. Amphibious-equipped float planes represent a higher investment, with an average cost of $340,000 on platforms like GlobalAir.com. High-end amphibious models capable of operating on both wheels and floats cost around $350,000. New multi-engine seaplanes designed for advanced operations command premium prices, reaching up to $3,000,000. Adding floats to an existing aircraft requires an expense ranging from $20,000 to $50,000, depending on the type and manufacturer. Used floats present a cost-effective alternative, priced at half the cost of new ones. The cost of a float plane varies based on factors including model, condition, and amphibious capabilities.