Propeller Plane: Definition, Types, Function, Difference, Speed

Jim Goodrich • • Reading time: 22 min

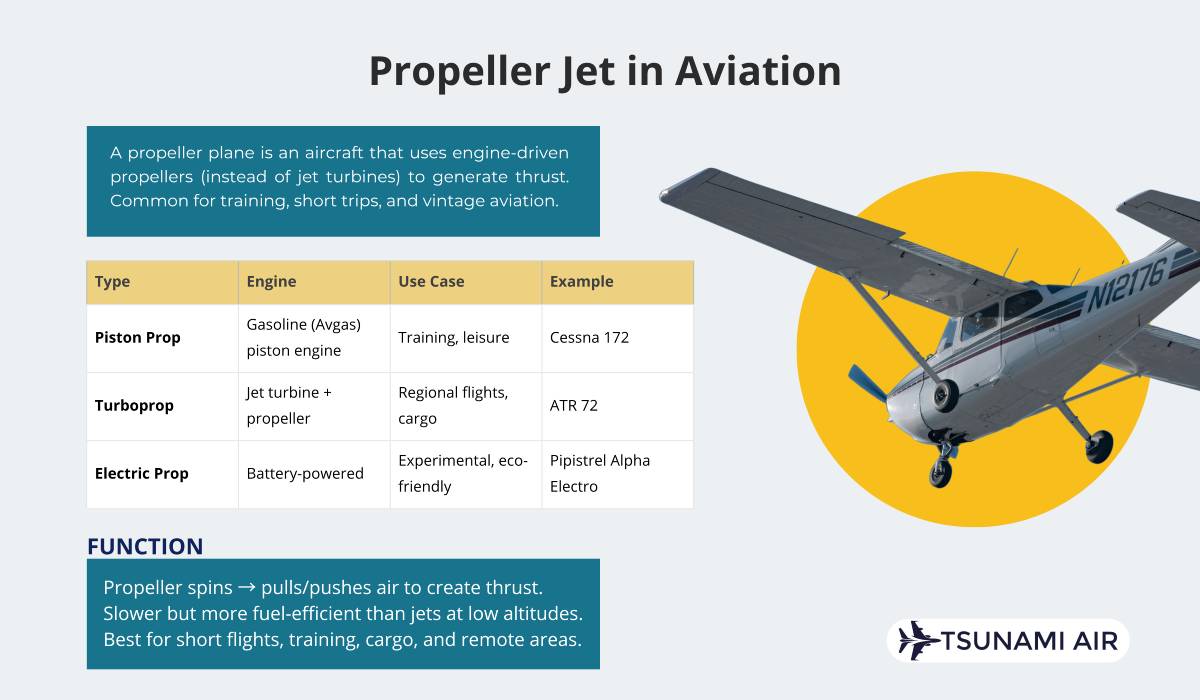

A propeller plane is an aircraft that generates thrust through a rotating propeller blade connected to an engine hub. The engine drives the propeller, creating the necessary force for flight. Propeller planes vary in types based on their wing configuration and operational design. Speed and performance depend on factors like the propeller's blade design and the aircraft’s overall structure. Understand the propeller plane's engine, flight mechanics, wing structure, and operational principles.

Propeller planes are classified into several types depending on their engines and configurations. Piston engine propeller planes achieve fuel efficiency with consumption rates of 5-10 gallons (19-38 liters) per hour, making them suitable for short to medium-range flights. Turboprop aircraft produce power outputs ranging from 500 to 1,500 horsepower, enabling speeds up to 300 knots for long-range missions. Single-engine propeller planes reduce maintenance complexity while twin-engine variants provide engine redundancy for better safety. Amphibious propeller aircraft feature specialized landing gear allowing operations on both water and land. Cargo propeller planes maximize payload capacity, accommodating hundreds of kilograms to several tons of cargo efficiently.

Propeller planes operate by converting rotary motion into aerodynamic lift directed forward as thrust. Engines deliver mechanical energy via a drive system, powering propellers at rotation speeds of 2,000–2,800 RPM. Propeller blades act as rotating airfoils, generating lift forces perpendicular to their surface sections. Blade pitch varies within a 10°–30° range, optimizing performance under different conditions. Aircraft engine power output ranges from 100–500 HP in piston engines and exceeds 1,000 HP in turboprops. Combustion process optimization achieves thermal efficiencies of 25–35% in piston engines.

Turboprop planes use gas turbine engines driving propellers, operating at speeds of 200–400 knots (370.4–740.8 kilometers per hour) and altitudes of 10,000–25,000 feet (3,048–7,620 meters). Jets rely on turbojet or turbofan engines, achieving speeds of 500–600 knots (926–1111 kilometers per hour) and cruising at altitudes of 30,000–50,000 feet (9144–15240 meters). Fuel efficiency favors turboprops for regional missions, consuming 100–150 gallons (378.5–567.8 liters) per hour compared to jets burning 200–1,000+ gallons (757.1–3,785.4+ liters) per hour. Turbofan engines emphasize bypass ratios to balance thrust output and noise reduction.

Propeller planes fly at optimal speeds balancing efficiency and performance. Most operate within a speed range of 250-400 mph (402.336-643.7376 km/h). Experimental aircraft like the Dornier Do 335 reached speeds up to 975 km/h (606 miles/h), but shock waves and compressibility issues prevented sustained supersonic flight. Propeller technology limits planes from reaching supersonic speeds, which require jet propulsion.

Larger propellers with a diameter of 22 feet 6 inches (6.858 meters) provide greater efficiency at lower speeds, utilized in specialized military aircraft. The largest airplane propeller ever used in flight had a diameter of 22 feet 6 inches (6.858 meters), demonstrating boosted efficiency at lower speeds.

What is a propeller airplane?

A propeller airplane is an aircraft that uses one or more propellers, powered by an engine, to generate thrust by converting rotary motion into a swirling slipstream that accelerates surrounding air. The power source of a propeller airplane is a piston engine or a gas turbine referred to as a turboprop in aeronautics. Propeller blades are shaped like wings with a twist along their length and create lift forces perpendicular to their surface section. The rotation of propeller blades produces forward thrust, which is the resolved unit of the lift vector, defined as the part that pulls or pushes the aircraft forward. The number of propeller blades varies between two and six, depending on the power and efficiency needs of the aircraft. Constant-speed propellers adjust their pitch to maintain a constant RPM, providing optimal performance throughout various phases of flight.

The fuselage of a propeller airplane houses the cockpit, fuel tanks, and engine. Aircraft structure integrates the fuselage with wings designed to generate lift through an aerodynamic profile. Propeller wings create a pressure difference between their upper and lower surfaces, resulting in lift that counteracts the aircraft's weight. Wing configurations vary depending on the intended use, ranging from straight designs for slower speeds to swept or delta shapes for higher performance aircraft. The wing aerodynamic profile directly influences flight efficiency by balancing lift generation with drag minimization.

Piston engines dominate smaller propeller airplanes, utilizing a four-stroke combustion cycle involving intake, compression, power, and exhaust strokes. Piston engine cylinder arrangements include inline, radial, or V-shaped designs, contributing to engine power output ranging from 100 to over 1,000 horsepower. Combustion mixes air and fuel within cylinders, converting chemical energy into mechanical energy transmitted to the propeller via a driveshaft. Turboprop engines combine gas turbine technology with a reduction gearbox driving the propeller. Turboprop engine efficiency surpasses piston engines at higher altitudes and speeds, achieving better fuel economy due to their higher power-to-weight ratio. Propeller airplane engines rely on an aircraft engine fuel system providing steady fuel delivery for optimal combustion.

Propulsion system energy conversion transforms rotational energy from the engine into thrust through the propeller. Propeller blades act as rotating wings, generating lift directed forward as thrust. Blade pitch plays a vital part in propeller thrust production, with higher pitch increasing efficiency at high speeds but reducing performance during takeoff. Fixed or variable blade pitch adjusts to optimize thrust based on flight conditions. Propulsion system thrust depends on the interaction between propeller blades and surrounding air, resolving into forward motion that propels the aircraft. Aerodynamic drag minimization ensures efficient energy use during flight.

Flight dynamics in propeller airplanes focus on balancing aerodynamic lift with drag forces. Wing configurations influence stability and efficiency, with straight wings providing better low-speed performance and swept designs boosting high-speed capabilities. Propeller airplane aerodynamics aim to minimize drag while maximizing lift and thrust generation. Drag forces impact overall efficiency, requiring streamlined fuselage shapes and optimized wing profiles to maintain stable and efficient flight. Aircraft design incorporates structural integrity with aerodynamic principles, guaranteeing reliable performance across various flight operations.

What are the types of propeller planes?

The types of propeller planes are outlined below.

- Piston engine propeller aircraft: Utilize air-cooled or liquid-cooled engines with fuel efficiency of 5-10 gallons (19-38 liters) per hour, ideal for short to medium-range flights and lower-altitude operations.

- Turboprop aircraft: Integrate turbine engines producing 500 to 1,500 horsepower, enabling speeds up to 300 knots for long-range missions.

- Single-engine propeller planes: Operate with one engine, reducing maintenance complexity and costs due to fewer components.

- Twin-engine propeller planes: Provide engine redundancy, boosting safety during engine failure scenarios for reliable emergency performance.

- Amphibious propeller aircraft: Feature specialized landing gear and propellers, allowing takeoffs and landings on both water and land for versatile remote access.

- Cargo propeller aircraft: Maximize payload capacity, carrying hundreds of kilograms to several tons, with interior space optimized for efficient logistics.

- Military propeller aircraft: Execute surveillance, transport, and combat support missions, equipped with advanced avionics, communication systems, and integrated armaments.

- General aviation propeller aircraft: Serve private flying, training, and sightseeing purposes, valued for reliability, cost-effectiveness, and versatility among pilots.

Piston engine propeller aircraft utilize air-cooled or liquid-cooled engines, defining their piston engine propeller aircraft engine type. These engines achieve fuel efficiency at lower altitudes and speeds, consuming 5-10 (18.92-37.85 liters) per hour, which aligns with their piston engine propeller aircraft fuel efficiency. Regular maintenance includes oil changes and spark plug replacements every 500 to 1,000 flight hours, addressing piston engine propeller aircraft maintenance requirements. Turboprop aircraft integrate turbine engines to drive propellers, showcasing turboprop aircraft engine type. These engines produce power outputs ranging from 500 to 1,500 horsepower, emphasizing turboprop aircraft power output. Speeds of up to 300 knots highlight turboprop aircraft speed capability, making them suitable for long-range flights. Single-engine propeller planes operate with one engine, reducing complexity and costs, central to single-engine propeller plane number of engines. Fewer components simplify maintenance, underscoring single-engine propeller plane operational simplicity.

Twin-engine propeller planes provide redundancy, allowing continued flight during engine failure scenarios, vital for redundancy. Amphibious propeller aircraft feature specialized landing gear and propellers, optimizing water operability. These aircraft perform takeoffs and landings on both water and land, demonstrating versatility. Cargo propeller aircraft maximize payload capacity, carrying loads from hundreds of kilograms to several tons, maximizing cargo propeller aircraft payload capacity. Interior space accommodates varying cargo volumes efficiently, needed for cargo volume. Advanced avionics and communication systems enhance operational effectiveness. Armaments like machine guns, rockets, or bombs integrate into military propeller aircraft armament integration. Reliability and cost-effectiveness make these aircraft popular among recreational and expert pilots, reinforcing general aviation propeller aircraft reliability.

What are some propeller planes used by the military?

Some propeller planes used by the military are listed below.

- Douglas C-47 Skytrain propeller planes: Known for troop and cargo transport during World War II, powered by two Pratt & Whitney R-1830 radial engines.

- Lockheed C-130 Hercules propeller planes: Tactical airlift aircraft capable of carrying large cargo over long distances with four Allison T56 turboprop engines.

- Fairchild C-123 Provider propeller planes: Tactical transport used extensively during the Vietnam War for supply missions and medical evacuations.

- Lockheed P-3 Orion propeller planes: Anti-submarine warfare aircraft equipped with advanced sensors and sonobuoys for detecting submarines.

- Boeing B-17 Flying Fortress propeller planes: Strategic bomber during World War II, capable of carrying up to 8,000 pounds of bombs.

- Consolidated PBY Catalina propeller planes: Amphibious patrol aircraft performing reconnaissance, rescue, and anti-submarine warfare during World War II.

- Embraer EMB 314 Super Tucano propeller planes: Modern light attack and counter-insurgency aircraft powered by a single Pratt & Whitney Canada PT6A turboprop engine.

The Douglas C-47 Skytrain cargo aircraft, an advanced version of the civilian DC-3 airliner, transports up to 28 troops or 6,000 pounds (2,721.56 kilograms) of cargo. Over 100 countries operate the Douglas C-47 Skytrain, which performs paratrooper deployments, glider towing, and parachute drops during World War II. Two Pratt & Whitney R-1830 Twin Wasp radial engines power the aircraft, each producing about 1,200 horsepower. The Fairchild C-123 Provider tactical transport carries up to 60 troops or 24,000 pounds (10,886.24 kilograms) of cargo. The Fairchild C-123 Provider cargo aircraft saw extensive use during the Vietnam War for supply missions and medical evacuations.

The Lockheed C-130 Hercules transport aircraft defines modern air mobility with its ability to carry up to 92 passengers, 64 paratroopers, or 42,000 pounds (19,050 kilograms) of cargo. Four Allison T56 turboprop engines, each producing 4,591 horsepower, equip the Lockheed C-130 Hercules. The Boeing B-17 Flying Fortress strategic bomber served during World War II as a key USAAF aircraft, carrying up to 8,000 pounds (3,628.74 kilograms) of bombs over a range of 2,000 miles (3,218.69 kilometers). Over 12,000 Boeing B-17 Flying Fortress World War II bombers are built, playing a central part in Allied strategic bombing campaigns. The Lockheed P-3 Orion maritime patrol aircraft performs anti-submarine warfare with advanced sensors and sonobuoys. Naval forces worldwide use the Lockheed P-3 Orion anti-submarine warfare aircraft, which detects and tracks submarines over a range exceeding 2,000 nautical miles.

The Consolidated PBY Catalina amphibious patrol aircraft lands on both water and land, performing reconnaissance and rescue missions. The Consolidated PBY Catalina amphibious patrol aircraft contributed to long-range maritime surveillance during World War II. The versatility of the Consolidated PBY Catalina reconnaissance aircraft extends to extended patrol missions, search-and-rescue operations, and anti-submarine warfare. The Embraer EMB 314 Super Tucano represents a new generation of propeller-driven military aircraft, performing light attack, counter-insurgency, and pilot training missions. These aircraft demonstrate enduring significance in military operations through their adaptability in transport, patrol, and combat roles.

How do propeller planes work?

Propeller planes work by using engines to drive propellers, generating thrust through aerodynamic principles. The propeller blades act as rotating airfoils to create aerodynamic lift forces that convert into forward thrust. Propeller planes rely on key aspects like propeller blade design, rotation speed, and efficiency for operation. Aircraft engine power output and fuel efficiency are vital factors in propeller plane performance. Aerodynamics play a vital function in the overall functionality of propeller planes. Wing geometry and angle of incidence optimize aircraft flight envelopes.

Propeller planes generate thrust through the aerodynamic lift forces created by propeller blades. Propeller blade design incorporates airfoil shape, curvature, and camber to optimize lift while minimizing drag. Airflow dynamics over the blades create a pressure differential between surfaces, producing forward thrust. Wing geometry and angle of incidence are decisive in optimizing lift generation and reducing drag flow separation. Airfoil shape and camber guarantee efficient pressure distribution, boosting lift force magnitude during flight. Drag air resistance and drag friction affect aircraft performance, requiring propellers to produce sufficient thrust to overcome these forces.

Aircraft engines deliver mechanical energy via a mechanical drive to power the propeller efficiently. Engine power output ranges from 100–500 HP in piston engines to over 1,000 HP in turboprops. Combustion process fuel-air mixture optimization achieves thermal efficiency between 25–35% in piston engines. Propeller rotation speed ranges from 2,000–2,800 RPM, impacting thrust force production. Propeller pitch blade angle varies within a 10°–30° range, allowing variable pitch systems to adjust for optimal performance under different conditions. Aircraft engine fuel efficiency depends on matching engine power to propeller demand, with fuel consumption rates in small engines ranging from 10–20 gallons per hour (37.85–75.7 liters per hour).

Interaction between propeller thrust and control surfaces ensures maneuverability and stability during flight. Thrust acceleration determines the net force acting on the aircraft, with efficient propellers maximizing takeoff and climb phases. Drag components include skin friction, pressure drag, and induced drag, influencing thrust requirements. Lift pressure differential over wings complements propeller thrust, with angle of incidence set between 2–6 degrees for optimized lift generation. Pressure distribution over both wings and propeller blades is fundamental to achieving balanced flight dynamics.

Private, commercial, and UAV propeller planes exhibit variations in functionality and design. Propeller efficiency ranges from 75–85%, depending on speed, pitch, and design specifications. Technological advancements have boosted modern propeller efficiency and aircraft capabilities, including variable pitch systems that enhance adaptability to varying flight conditions. Wing lift generation relies on optimized wing geometry and airflow dynamics, with lift coefficients ranging from 1.3–1.5 for typical small aircraft during takeoff. Energy conversion transforms chemical energy into mechanical energy, driving the propeller and maintaining stable flight operations. Propeller planes work by combining engine mechanics, aerodynamic principles, and advanced designs to achieve efficient propulsion and handling.

How does a propeller plane engine work?

A propeller plane engine works by generating power through internal combustion, which drives the propeller to produce thrust. The engine operates on a four-stroke cycle, including intake, compression, power, and exhaust strokes, providing efficient energy conversion. Air and fuel mix in a precise 15:1 ratio during the intake stroke, optimizing combustion efficiency. Spark plugs ignite the compressed fuel-air mixture at high pressure, around 10 to 15 bar, releasing energy during the power stroke. The piston's reciprocating motion converts into rotational energy through the crankshaft, which connects to the propeller via a gear reduction system. Propeller blades, designed with aerodynamic camber, generate thrust by accelerating airflow, achieving efficiencies of 80%.

Piston engines and turboprops represent the primary types of engines used in propeller planes. Piston engines operate on a four-stroke cycle, optimizing engine power generation through precise fuel system mixture regulation. Turboprop engines utilize a turbine to drive the propeller via a gear reduction system torque conversion, achieving higher power-to-weight ratios. The choice of engine impacts performance characteristics, with piston engines excelling in smaller aircraft and turboprops offering superior efficiency for larger planes. Design adaptations in engine block and gearbox configurations cater to specific operational needs like aircraft size and mission type.

The energy conversion process begins with the combustion process fuel combustion, where chemical energy transforms into mechanical energy. During the compression stroke, the piston compresses the internal combustion engine fuel-air mixture to a pressure range of 10 to 15 bar. Ignition system spark timing ensures optimal ignition of the mixture during the power stroke, releasing energy that drives the piston downward. This reciprocating motion is converted into rotational energy through the crankshaft rotational conversion. The crankshaft mechanical linkage transfers this energy to the propeller, enabling efficient propulsion.

Propeller function relies heavily on propeller blade design, which incorporates aerodynamic camber to accelerate airflow and generate thrust. Propeller pitch control adjusts the blade angle, optimizing thrust at varying speeds and contributing to propeller aerodynamic efficiency. The efficiency of propellers reaches up to 80%, influenced by factors like blade shape and operational parameters. Air flow regulation ensures clean air enters the engine, while exhaust system pressure relief manages backpressure, maintaining overall engine performance.

Main components like the engine block, piston assembly, and gearbox interact to achieve smooth operation. The piston displacement determines the volume of the air-fuel mixture ignited during each stroke, impacting power output. Fuel delivery systems guarantee precise fuel injection or carburetor-based mixing, aiding combustion process energy release. Gear reduction systems reduce speed while increasing torque, enabling the propeller to operate efficiently. Adaptations in these components address environmental factors and mission requirements, allowing reliable engine-propeller integration for optimal propeller plane propulsion efficiency.

What is the difference between a turboprop plane and a jet?

The difference between a turboprop plane and a jet is explained in the table below.

Feature | Turboprop Plane | Jet Plane |

Propulsion System | Gas turbine engine driving a propeller via reduction gearbox | Turbojet or turbofan engines generating thrust entirely from exhaust gases or bypass airflow |

Thrust Mechanism | Thrust generated primarily by propeller blades | Thrust generated by exhaust gases or bypass air |

Operating Speed | 200–400 knots (370.4–740.8 km/h) | 500–600+ knots (926–1,111.2+ km/h) |

Cruising Altitude | 10,000–25,000 feet (3,048–7,620 m) | 30,000–50,000 feet (9,144–15,240 m) |

Fuel Consumption | 100–150 gallons per hour (378.5–567.8 liters/h) | 200–1,000+ gallons per hour (757–3,785+ liters/h) |

Efficiency | High fuel efficiency for short- to medium-range flights | Higher fuel consumption but efficient for long- haul missions |

Performance Adjustment | Adjustable propeller pitch optimizes performance during takeoff, climb, and cruise | Consistent thrust without adjustable mechanisms |

Typical Use Cases | Regional, short-haul, and unpaved runway operations | Long-haul, high-speed travel; commercial airliners and military applications |

Engine Design | Gas turbine connected to a propeller through reduction gearbox | Turbofan engines with bypass ratios for improved efficiency and noise reduction |

Turboprops adapt performance through adjustable propeller pitch, while jets maintain consistent thrust without propellers. The turbine extracts energy from exhaust gases to rotate the shaft linked to the gearbox, which transmits mechanical power to the propeller blades.Pilots adjust propeller pitch to optimize performance under varying flight conditions. Turbofan engine cycles emphasize efficiency through increased bypass ratios, balancing thrust output and noise reduction.

What is a Delta propeller plane?

A Delta propeller plane is any propeller-driven aircraft operated by Delta Air Lines, featuring models like the Douglas DC-7 and Convair 440. Delta Air Lines historically operated propeller aircraft like the Douglas DC-3, DC-4, and DC-7, alongside Convair 340 and 440 models. The Douglas DC-7 achieved a cruise speed of 365 miles per hour (587 kilometers per hour), making it the fastest piston-powered commercial plane of its era. These aircraft featured wing designs optimized for long-distance flights, with the DC-7 offering a range exceeding 3,000 miles (4,828 kilometers). Delta's transition from propeller planes to jet engines marked a pivotal shift in aviation history, symbolizing the end of the piston-engine age. Enthusiasts contemplating these planes gain insights into specifications like seating capacity, wing span, and maintenance techniques that define their operation.

Delta propeller plane configuration integrates delta wing geometry with a propeller-driven propulsion system, allowing high-speed aerodynamics and efficient thrust generation. Delta wing aerodynamics enhance lift through rearward sweep and conical leading edge droop, maintaining subsonic flow characteristics over the wing. Propeller blade design optimizes pitch, camber, and number of blades to complement the delta wing configuration. Aircraft structure supports both the robust fuselage and the integration of the propulsion system, handling stresses from high-speed flight and propeller operation. The propulsion system mechanism involves engines driving propellers via gearboxes, converting rotational energy into thrust while minimizing drag.

Aircraft aerodynamics in delta propeller planes rely on airflow patterns created by delta wings. Rearward sweep reduces airspeed normal to the leading edge, boosting lift without increasing drag. Delta wing lift maintains stable flight at transonic speeds due to unique properties. Aircraft stability depends on balancing airflow interactions between the propeller and the delta wing. Placement of the propeller above or below the wing minimizes interference with lift generation. Integration of the propulsion system ensures seamless airflow around the aircraft structure.

Propulsion system power in delta propeller planes requires advanced engine designs to optimize fuel economy and structural integrity. Engines produce sufficient thrust to achieve desired speeds while maintaining efficiency. Propeller efficiency directly affects overall aircraft performance, influencing range and speed capabilities. Delta propeller plane performance achieves high-speed capabilities with efficient propulsion at lower speeds. Historical models like the H-5A Delta Stinger demonstrate the impact of combining delta wings with propellers on aviation advancements.

How fast do propeller planes fly?

Propeller planes fly at speeds below 480 mph (772.49 kph) due to subsonic airspeed limits. Most propeller planes operate within an optimal speed range of 250-400 mph (402.336-643.7376 km/h), balancing efficiency and performance. Turboprop engines achieve their best fuel economy within this range, making them ideal for regional flights. Experimental aircraft like the Dornier Do 335 reached speeds up to 975 km/h (606 mph), showcasing rare exceptions. Shock waves and compressibility issues prevent sustained supersonic flight in propeller-driven designs. Theoretical limits cap propeller plane speeds below Mach 1, 768 mph (1,236 km/h).

Turboprop engines operate optimally within a speed range of 250-400 mph (402-644 km/h), balancing fuel economy and performance. This range suits regional flights where efficiency matters more than raw speed. Most propeller planes fly at subsonic airspeed limits of about 480 mph (772.48 km/h) due to structural and aerodynamic constraints. Rare exceptions include the Spitfire Mark XI which reached 606 mph (975.2 km/h) in a 45° dive and Squadron Leader Martindale’s test flight that achieved 620 mph (997.8 km/h) under specific conditions. Experimental aircraft like the Dornier Do 335 achieved the fastest recorded speed of 975 km/h (606 mph) in controlled tests. Shock waves and compressibility issues prevent sustained supersonic flight, keeping propeller planes below Mach 1, 768 mph (1,236 km/h). The Tu-114 turboprop model demonstrates advanced capabilities with a top speed of Mach 0.73, equivalent to around 560 mph (901 km/h). Commercial turboprop planes cruise at speeds of 800-900 km/h (500-560 miles/h) but rarely exceed their optimal efficiency range during regular service. Propeller technology limits planes from reaching supersonic speeds, making jet propulsion necessary for such achievements.

How far can a prop plane fly?

The distance a prop plane can fly depends on its size, type, fuel capacity, and specific design characteristics. A typical single-engined prop plane at cruising speed achieves a range of 400 to 600 nautical miles. Smaller aircraft like the Piper Super Cub fly 500 miles (804.672 kilometers). Larger single-prop planes like the DHC Otter reach ranges of up to 1,000 miles (1,609 kilometers). The Cessna 182 Skylane travels between 900 (1448.41 kilometers) and 1,000 (1609.34 kilometers) miles depending on conditions. Efficient propeller-driven aircraft cover distances of 700 (435 miles) to 1,000 (621 miles) kilometers for mid-range trips.

Higher performance turboprops and business jets exhibit advanced capabilities, achieving ranges of 1,000–2,500 kilometers (621–1,553 miles). Technological advancements in engine design and aerodynamics enable these aircraft to fly longer distances. Turboprop or business jets with higher performance cater to regional travel demands while maintaining operational efficiency.

What is the role of propeller planes in commerce?

The role of propeller planes in commerce is to enhance commercial aviation regional connectivity through fuel efficiency, cargo capacity, and operational versatility. Propeller planes achieve high fuel efficiency, consuming up to 30% less fuel than jets on short-haul routes. Turboprop aircraft like the Cessna 208 Caravan carry payloads of up to 2,000 kg (4,409 lbs), optimizing regional cargo operations. Short takeoff and landing capabilities enable access to runways under 1,000 meters (3,280 feet), boosting connectivity in remote areas. Operational flexibility allows turboprops to operate from non-concrete surfaces, reducing infrastructure costs. Lower maintenance requirements and operational expenses elevate profitability in regional aviation markets.

Propeller planes transport goods, passengers, and mail efficiently in regional markets. Air cargo freight capacity in turboprops like the Cessna 208 Caravan reaches up to 2,000 kg (4,409 lbs), aiding diverse logistical needs. Regional air transport local connectivity enhances supply chains by incorporating smaller communities into broader networks. Commercial aviation market penetration expands as propeller plane operational versatility allows operations on non-concrete runways and shorter airstrips under 1,000 meters (3,280 feet). Freight operations turnaround time decreases due to quick loading and unloading capabilities, guaranteeing timely deliveries.

Operational efficiency in propeller planes stems from fuel efficiency, consuming 30% less fuel than jets on short-haul routes. Commercial aviation cost effectiveness improves through lower maintenance requirements and reduced operational expenses. Aviation logistics supply chain integration benefits from propeller plane short takeoff performance, accessing remote areas with limited infrastructure. Airline service frequency increases as turboprops achieve quick turnaround times, maintaining reliable schedules for regional flights.

Historical developments show propeller planes dominated early commercial aviation before jets took over long-haul routes. Contemporary relevance highlights turboprops excelling in regional air transport short haul performance, covering distances under 500 miles (804.67 kilometers) effectively. Technological advancements enhance propeller plane cargo capacity and air cargo delivery speed, meeting modern commerce demands. Regulatory frameworks support their role by emphasizing environmental adaptability and cost-efficient operations.

Propeller planes achieve air cargo cost efficiency through lower fuel consumption and operational costs. Cargo transport logistics integration ensures seamless movement of goods across diverse routes. Regional air transport cost effective operations sustain profitability in smaller markets. Aviation logistics network management adapts to varying demands, optimizing inventory levels and scheduling. Airline services’ regional connectivity strengthens as propeller planes link isolated areas to major hubs, fostering economic growth.

What is the size of propeller planes?

The size of propeller planes is given in the table below.

Category | Propeller Diameter | Application/Use Case | Additional Notes |

General Aviation Aircraft | 1.4 m - 1.8 m (4.59 ft - 5.91 ft) | Small to medium aircraft | Corresponds to 4.6 ft (1.4 m) - 6.0 ft (1.8 m) |

Model Aircraft or Drones | 6 inches (15.24 cm) | High RPM requirements | Smaller propellers for efficiency in small-scale models |

Specialized Military Aircraft | 22 ft 6 in (6.86 m) | Enhanced efficiency at lower speeds | Largest propeller ever used in flight |

Classified by Diameter/Pitch | d.2750/p.2550 | Specific applications requiring precision | 2750 mm (108.27 in) diameter |

10x6 Propeller | 10 inches (25.4 cm) | Standard small aircraft | Diameter of 10 inches (25.4 cm), pitch of 6 inches (15.24 cm) |

8x6 Propeller | 8 inches (20.32 cm) | Clearance-constrained designs | Used in smaller aircraft |

Safety Minimum Clearance | 9 inches (22.86 cm) | Prevent interference during operation | Tail-up clearance during operation |