Turboprop Plane: Definition, Function, Configuration, Difference

Jim Goodrich • • Reading time: 32 min

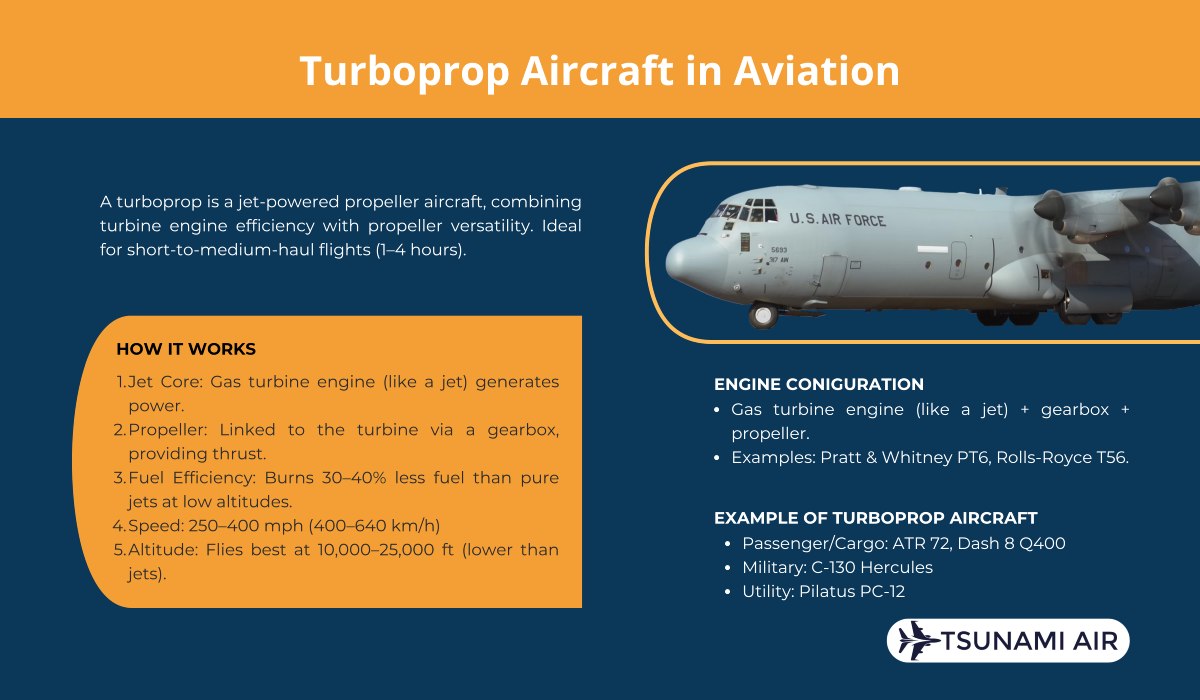

A turboprop plane is a type of aircraft powered by a turbine engine connected to a propeller. The engine drives the propeller to generate thrust for flight. Turboprop planes achieve efficient performance during takeoff and maintain reliable range capabilities. These aircraft feature distinct configurations optimized for specific operational needs. Understand the turboprop plane's engine, range, propeller design, and features.

Turboprop engines operate through a gas turbine cycle where air enters the intake system and gets compressed in multiple stages. Fuel mixes with compressed air in the combustion chamber, igniting to produce high-pressure gases. These gases drive the turbine, extracting energy to power both the compressor and the propeller via a reduction gearbox. Aerodynamic propeller blades convert rotational energy into thrust, optimizing efficiency at speeds between 200 and 350 knots.

The difference between a turboprop and a propeller lies in the propulsion mechanism. A turboprop uses a gas turbine engine to drive the propeller, while a traditional propeller relies on a piston engine. Turboprops include components like an intake, compressor, combustor, turbine, and reduction gearbox.

Turboprop engines reduce structural weight, elevating aerodynamics and decreasing fuel consumption by up to 40% compared to jet engines. Enhanced payload capacity allows carrying more cargo or passengers, making turboprop aircraft versatile for various missions. Low specific fuel consumption translates to cost savings for regional flights under 500 nautical miles.

Small single-propeller planes cruise at speeds of 125 knots (144 mph), while turboprop engines optimize performance within the speed range of 250 to 400 mph (402 to 644 km/h). Commercial turboprop models like the Beechcraft King Air 350 cruise at speeds up to 320 ktas (368 mph), and the ATR 72 operates at speeds reaching 270 ktas (310 mph).

What is a turboprop airplane?

A turboprop airplane is an aircraft that uses a gas turbine engine to drive a large propeller, providing efficient thrust for flight at lower speeds. Turboprop engines use a gas turbine core to generate power, with most energy directed to turn a large propeller through a reduction gearbox. The propeller creates thrust by driving air backward, optimizing efficiency at speeds between 200 and 350 knots. Regional aviation sectors favor turboprop aircraft for short to medium distances, using 30% less fuel compared to jets. Modern turboprop designs, like the Kodiak, incorporate advanced materials and avionics to enhance performance. Turboprop engines excel in remote area operations, relying on their ability to produce high power at low flight speeds.

Turboprop engines generate thrust through a gas turbine core that drives a propeller via a gear reduction system. The turbine mechanism converts energy from hot gases into mechanical power, which turns the propeller. Propeller pitch control adjusts the angle of the blades to optimize efficiency under varying flight conditions. Modern turboprop designs incorporate advanced materials and avionics, elevating performance and reliability. Large-diameter propeller blades accelerate a volume of air backward, producing efficient thrust at speeds between 200 and 350 knots. This configuration ensures high power output at low speeds, making turboprop aircraft ideal for short to medium distances and operations in remote areas.

Regional aviation sectors favor turboprop airplanes due to their cost-effectiveness and fuel efficiency, consuming 30% less fuel compared to jets. Military operations utilize turboprops for their robustness and ability to perform in challenging terrains. Examples of prominent turboprop models include the ATR 72, Cessna 208 Caravan, and Beechcraft King Air 350, manufactured by companies like Beechcraft, Cessna, and ATR. Variations in airframe design, like high-wing configurations, accommodate engine mounts and propeller requirements while reducing interference drag. Turboprop airplanes operate efficiently at lower altitudes and speeds, leveraging STOL capabilities for use on shorter runways and smaller airports.

What is a turboprop cargo aircraft?

A turboprop cargo aircraft is a robust and efficient airplane powered by a gas turbine engine that drives a propeller, making it ideal for regional transport and freight operations requiring high payload capacity and versatility. Turboprop cargo aircraft are powered by a gas turbine engine that drives a propeller through a reduction gearbox. The engine consists of an intake, compressor, combustor, turbine, and propelling nozzle, forming the core of its efficient design. Air enters the intake and compresses before fuel mixes with it in the combustor, generating hot gases that expand through the turbine stages. Turboprop engines provide high payload capabilities, making them ideal for regional freight operations requiring versatility and efficiency. Freight operations benefit from turboprop cargo aircraft's ability to operate on shorter runways and in remote locations.

Turboprop aircraft performance highlights their ability to operate on shorter runways and in remote locations. Turboprop engines generate thrust by extracting energy from exhaust gases through a turbine, which drives the propeller via a reduction gearbox. The gearbox allows the engine to maintain high rotational speeds while the propeller operates efficiently at slower speeds. Aircraft propeller rotation depends on blade design optimized for maximizing thrust while minimizing drag. Turboprops achieve efficient propulsion at lower speeds, up to 210 knots (389 km/h), making them ideal for regional air cargo freight missions.

Turboprop aircraft efficiency stems from their fuel economy and suitability for short to medium-haul flights. The Pratt & Whitney Canada PT6 engine produces up to 2,000 horsepower, demonstrating power output relative to size. Turboprop engine components include an intake, compressor, combustor, turbine, and propelling nozzle, all working together to convert combustion energy into mechanical power. Aircraft propeller aerodynamics focus on optimizing lift and drag characteristics for efficient flight at altitudes up to 35,000 feet (10,668 meters). Turboprop aircraft configuration features high-wing designs, elevating ground clearance and stability during cargo loading and unloading.

Cargo aircraft structure prioritizes spacious interiors and reinforced frames to handle heavy payloads and frequent operations. The Cessna SkyCourier offers a payload capacity of 6,000 pounds (2,722 kg) and a cargo door measuring 7 ft 3 in by 5 ft 9 in (2.2 m x 1.75 m). Air cargo logistics benefit from advanced systems like cargo nets, multiple attach points, and seat rail attach points, allowing safe and efficient freight handling. Cargo hold designs accommodate oversized and high-volume shipments, increasing flexibility for air cargo shipment volume. Turboprop cargo aircraft systems integrate robust avionics and structural reinforcements to support reliable operations in diverse environments.

How do turboprop engines work?

Turboprop engines work by combining gas turbine technology with a propeller to generate thrust. Air enters the engine through the intake system, where it is filtered and managed for optimal efficiency. The axial compressor compresses the air in multiple stages, increasing its pressure and temperature before directing it into the combustion chamber. Fuel mixes with the compressed air and ignites, producing high-pressure gases that drive the turbine. The turbine extracts energy from these gases to power both the compressor and the propeller via a reduction gearbox. Aerodynamic propeller blades convert rotational energy into thrust, maximizing efficiency while minimizing drag.

The thermodynamic process in a turboprop engine involves three key stages: air compression, combustion, and gas expansion. Air enters the engine through the intake system, where it undergoes filtration and airflow management to guarantee smooth operation. The axial compressor compresses the incoming air in multiple stages, increasing its pressure and temperature before directing it into the combustion chamber. Fuel mixes with the compressed air in the combustion chamber, igniting to produce high-pressure and high-temperature gases. These gases expand and flow over the turbine blades, extracting energy to drive both the compressor and the propeller. Gas turbine energy conversion occurs as the turbine transforms thermal energy from combustion into mechanical rotational force.

Mechanical operation of the turboprop engine follows a defined airflow path from intake to exhaust. Air enters through the air intake inlet, optimized for airflow management and filtration to maintain efficiency. After passing through the axial compressor, the compressed air moves into the combustion chamber for fuel ignition. High-pressure gases exiting the combustion chamber drive the turbine, which transmits power through the reduction gearbox. The reduction gearbox performs gear reduction to match the high-speed rotation of the turbine to the optimal operational speed of the propeller. This ensures efficient thrust generation while minimizing energy loss during power transmission.

Turbine and propeller interaction is central to the turboprop engine propulsion mechanism. The turbine extracts energy from hot gases produced during combustion, converting it into rotational mechanical output. This energy powers the propeller via the reduction gearbox, which ensures proper speed conversion for aerodynamic efficiency. Propeller blade design is vital in thrust production, as the blades are engineered to maximize propeller aerodynamic efficiency. Aerodynamic blades push air backward to generate forward motion, balancing thrust generation with minimal drag. The reduction gearbox couples the turbine and propeller mechanically, providing reliable power transmission throughout the system.

Turboprop engines achieve better fuel economy at lower speeds and altitudes, making them suitable for short-range flights and regional operations. Unlike turbofan engines, turboprop engines rely on propeller thrust generation rather than jet thrust, resulting in reduced fuel consumption. Maintenance requirements for turboprop engines are simpler than those for piston engines, contributing to their reliability. Noise levels remain higher compared to turbofans but are offset by operational advantages in specific use cases like general aviation and cargo transport.

What is a single engine turboprop?

A single-engine turboprop is an aircraft powered by a single turboprop engine, designed for optimal performance in short to medium-range flights with cost advantages and versatility for personal and executive transport. A single turboprop engine drives a propeller through a gas turbine mechanism, allowing efficient performance. The compressor compresses air and mixes it with fuel in the combustor, producing hot gases that power the turbine stages. Single-engine turboprops operate effectively on unprepared runways, showcasing their versatility in various environments. Popular models like the Pilatus PC-12 and Daher-Socata TBM series offer comfortable cabin spaces and competitive performance for up to four passengers plus crew. High-altitude air masses affect single-engine turboprop engine performance due to gas density variations, requiring careful flight planning.

The gas turbine combustion chamber in a single engine turboprop achieves high thermal efficiency by compressing air and mixing it with fuel before ignition. The resulting hot gases drive the turbine stages, which transfer power through a concentric shaft to a gearbox. This gearbox reduces engine speed while increasing propeller efficiency. Propeller blade design plays an important part in thrust production, with optimized shapes and angles guaranteeing maximum aerodynamic efficiency. Up to 95% of the thrust is generated by the propeller, while 5% comes from residual jet thrust at the exhaust nozzle. Pilatus PC-12 and Beechcraft Denali are examples of single engine turboprop aircraft that benefit from advanced propeller designs.

Aircraft airframe configuration in single engine turboprops is specialized for optimal performance in short to medium-range operations. High-wing or low-wing designs enhance lift and minimize drag, aiding efficient operation at lower speeds and altitudes. High-altitude air masses affect engine performance due to variations in gas density, requiring careful flight planning. Single engine turboprops like the Pilatus PC-12 achieve a cruise speed of 320 knots and a range of up to 1,800 nautical miles. These aircraft consume between 40 (151.4 liters) and 60 (227.1 liters) gallons of fuel per hour at cruise, making them more economical than jets for regional flights.

The single engine turboprop market includes popular models like the Pilatus PC-12, Daher-Socata TBM series, and Beechcraft Denali. These aircraft are valued for their versatility, reliability, and operational simplicity. Pilots operating single engine turboprops undergo specialized training in engine management, propeller handling, and emergency procedures. Advanced avionics systems enhance safety when operating on unprepared runways or in diverse environments. Redundant systems and rigorous maintenance protocols guarantee consistent aircraft operational safety.

Single engine turboprops offer a balance between performance and cost efficiency compared to multi-engine turboprops or jets. The Pilatus PC-12 exemplifies this class with its Pratt & Whitney PT6A-67P engine producing up to 1,200 shaft horsepower. The Beechcraft Denali features a GE Catalyst engine rated at 1,300 shaft horsepower, combining robust turboprop engine power output with advanced propulsion systems. These aircraft serve roles in personal transport, executive travel, and utility missions, showcasing their adaptability across various sectors.

What are the characteristics of twin prop planes?

The characteristics of twin prop planes are outlined below.

- Twin prop planes leverage advanced aerodynamics to optimize lift and minimize drag, guaranteeing efficient performance at lower speeds.

- Turboprop engines like the Pratt & Whitney Canada PW127 deliver up to 2,750 shaft horsepower, boosting power output while maintaining fuel efficiency in twin prop planes.

- Fuel consumption in models like the ATR 72 is lower than comparable jet aircraft, reducing operational costs for regional flights operated by twin prop planes.

- Safety features in twin prop planes include redundant flight control systems and emergency backup systems, allowing continued operation during engine failure scenarios.

- Aircraft configuration structural design in twin prop planes incorporates lightweight materials like carbon fiber, boosting both durability and performance.

- Dual-engine configurations distinguish twin prop planes from single propeller aircraft, offering superior engine redundancy and reliability.

- Propeller propulsion efficiency in twin prop planes achieves higher thrust conversion at speeds below 300 knots, making them ideal for short-haul flights.

- Applications of twin prop planes span commercial regional aviation, cargo transport, and specialized military missions due to their versatile design.

- Short runway performance takeoff distance is vital for twin prop planes, with the ATR 72 operating effectively from runways as short as 1,900 feet (579 meters).

- Maintenance considerations for twin prop planes benefit from simpler engine designs, reducing downtime and repair costs compared to jet aircraft.

- Industry standards mandate rigorous certification for twin prop planes, emphasizing turboprop engine reliability and structural integrity.

- Comparative analysis shows twin prop planes outperform single-engine counterparts in engine redundancy backup systems and operational effectiveness.

- Historical benchmarks highlight consistent safety and efficiency in twin prop planes, with models like the Beechcraft King Air 360 demonstrating long-term reliability.

- Fuel efficiency and operational cost advantages are evident in twin prop planes like the Tecnam P2006T, which features a max range of 1,100 nautical miles.

- Flight control systems in twin prop planes enhance situational awareness, guaranteeing safe and efficient operations through precise avionics monitoring.

Aerodynamics lift is elevated in twin prop planes by advanced wing designs, while aerodynamics drag is minimized through optimized aircraft configuration structural design. Aircraft configuration layout includes rear passenger boarding and adaptable cabin spaces, aiding diverse operational needs. Emergency systems, like redundant flight controls and backup power units, guarantee engine redundancy safety during vital phases of flight.

What are the benefits of a multi-engine turboprop?

The benefits of a multi-engine turboprop are outlined below.

- Multi-engine turboprops provide better safety through engine redundancy, allowing continued flight with one engine inoperative, which reduces the risk of accidents during vital phases.

- The high power-to-weight ratio of multi-engine turboprops enables access to shorter and less defined airstrips, benefiting operations in remote airfields.

- Fuel efficiency in multi-engine turboprops leads to cost savings, with average burn rates ranging from 60 (227.12 liters) to 120 (454.25 liters) gallons per hour, ideal for short-haul flights.

- Maintenance costs for multi-engine turboprops remain low due to fewer moving parts in turboprop engines, resulting in longer intervals between overhauls and reduced downtime.

- Multi-engine turboprops achieve cruise speeds of 250 to 350 knots, offering performance speed and agility for diverse missions like passenger transport or cargo carriage.

- Payload flexibility in multi-engine turboprops supports weights exceeding 5,000 pounds (2,268 kilograms), making them suitable for executive transport or specialized missions.

- Operational reliability of multi-engine turboprops ensures consistent performance, with fewer components lowering the frequency of maintenance overhauls.

- Safety risk mitigation in multi-engine turboprops is achieved through asymmetric flight training and certification, boosting pilot preparedness during engine failures.

- Economic viability of multi-engine turboprops stems from their cost-effectiveness on regional routes, particularly those requiring access to remote airfields with shorter runways.

- Technical performance metrics of multi-engine turboprops highlight high power-to-weight ratios, enabling faster ascent and maneuverability in challenging conditions.

Turboprop engine efficiency surpasses that of jets at altitudes below 25,000 feet (7620 meters), providing fuel savings for short-haul flights. Multi-engine configuration redundancy ensures safe landings at nearby airports, even with one engine inoperative. Contrasts with single-engine turboprops highlight superior safety and performance metrics, while comparisons to jets emphasize turboprop engine power and operational feasibility. Multi-engine turboprops deliver a reliable platform for stakeholders seeking operational reliability availability across varying environments.

What is a rear engine prop plane called?

A rear engine prop plane is called an aircraft with a pusher configuration. The aircraft features a rear-mounted engine and propeller at the aft end of the airframe. The pusher configuration is distinct from the traditional tractor configuration. Propeller thrust generation follows the principle \( T = \dot{m} \Delta v \), producing forward motion. Rear engine placement improves pilot visibility by eliminating obstructions. Cabin noise levels are lower due to the engine's position away from the cockpit.

Rear engine placement in aircraft design refers to the installation of the engine at the aft end of the fuselage, a defining characteristic of a rear-mounted pusher configuration engine aircraft. Historical examples include the Curtiss Pusher from the early 20th century, while modern interpretations feature advanced turbo engine integration. Rear engine placement improves forward visibility by eliminating obstructions caused by a front-mounted propeller. Cabin noise levels are reduced as the engine and exhaust systems are positioned further from the cockpit and passenger areas. Aerodynamic efficiency benefits from smoother airflow over the wings and fuselage, although disturbed air behind these surfaces reduces propulsive efficiency.

Propeller-driven designs in rear-engine prop planes encompass both piston-engine and turboprop configurations. Piston engines generate between 100–300 hp (75–225 kW), while turboprop power plants produce 500–2,000 hp (370–1,500 kW). Turboprop aircraft achieve high power-to-weight ratios and excel in fuel efficiency at moderate speeds and altitudes. Propeller blade design incorporates optimized angles to accommodate the disturbed airflow in pusher configurations. Propeller rotation mechanisms involve shafts spinning at speeds ranging from 1,000–2,500 rpm, depending on the engine type. Thrust generation adheres to the principle \( T = \dot{m} \Delta v \), providing consistent performance regardless of engine placement mounting location.

The term "pusher" describes the rearward location of the engine and propeller, contrasting with the traditional tractor configuration. Pusher configuration aerodynamic design allows for unconventional layouts like flying wings or canard aircraft, which benefit from better weight distribution and stability. Rear-engine prop plane design classification includes both conventional fuselage layouts like the Bede BD-5 and innovative models like the Piaggio P.180 Avanti. Operational use cases highlight the advantages of reduced noise, boosted visibility, and adaptability to specific mission requirements.

What is the difference between a turboprop and a propeller?

The difference between a turboprop and a propeller is explained in the table below.

Aspect | Turboprop | Propeller |

Definition | A turboprop uses a gas turbine to drive the propeller. | A propeller is a device that converts rotational energy into thrust. |

Energy Source | Gas turbine engine | Rotational energy from an engine (turbine or piston-driven). |

Key Components | Intake, compressor, combustor, turbine, reduction gearbox, propelling nozzle. | Blades, hub, pitch control mechanism. |

Airflow Process | Air enters the intake, gets compressed, mixed with fuel in the combustor, and hot gases expand through turbine stages to drive the propeller. | Air is accelerated rearward by the propeller blades, creating forward thrust. |

Reduction Gearbox Role | Adjusts high RPM output of the turbine to match optimal propeller speed. | Not applicable (unless paired with a turbine or piston engine). |

Efficiency | High efficiency at lower altitudes and speeds. Fuel consumption is lower for regional flights. | Efficiency depends on blade design and angle of attack; performs well at lower speeds. |

Energy Production | Gas turbine combustion ensures continuous energy production | Piston engine mechanical design relies on discrete strokes |

Power-to-Weight Ratio | Higher power-to-weight ratio compared to piston engines. | Lower power-to-weight ratio when driven by piston engines. |

Blade Design | Optimized for aerodynamic performance, often with variable pitch control. | Blade pitch and diameter influence thrust generation. |

Engine Placement | Typically mounted on wings or fuselage; high-wing designs enhance ground clearance. | Front-mounted on piston engines; placement varies depending on aircraft configuration. |

Applications | Ideal for regional flights, shorter distances, and slower speeds. | Used in general aviation, small aircraft, and as part of piston or turboprop systems. |

What is the difference between a turboprop and a turbine?

The difference between a turboprop and a turbine is explained in the table below.

Parameter | Turboprop Engine | Turbine (General Gas Turbine) |

Core Mechanism | Uses a gas turbine core to drive a propeller. | General term for engines using a gas turbine. |

Propulsion Method | Propeller thrust (90% of energy). | Exhaust thrust (dominant in jet engines). |

Gearbox System | Gear ratios: 10:1 to 20:1. | Not applicable (direct exhaust thrust). |

Gearbox Efficiency | >95% mechanical efficiency. | N/A |

Optimal Altitude | Below 25,000 feet (7,620 meters). | 35,000–45,000 feet (10,668–13,716 meters). |

Optimal Speed | 200–400 knots (370–740 km/h). | >450 knots (833.4 km/h). |

Exhaust Thrust Contribution | <10% of total propulsion. | Dominant in jet engines (turbojets, turbofans). |

Fuel Efficiency | High at moderate speeds and lower altitudes. | Lower at high speeds compared to turboprops. |

Engine Core Speed | 30,000–40,000 RPM (reduced by gearbox). | 30,000–40,000 RPM (direct use of exhaust). |

Applications | Short-haul missions, regional flights (500–1,500 nautical miles). | Long-range flights (>3,000 nautical miles). |

Propeller Blade Design Focus | Aerodynamic efficiency for thrust generation. | N/A |

Power Transmission | Mechanical through gearbox to propeller. | Direct exhaust gas propulsion. |

Example Use Cases | Turboprop aircraft like Cessna Caravan. | Turbojets, turbofans, and turboshafts. |

Turboprop propeller integration ensures optimal thrust generation through precise blade design. The propeller rotational dynamics critically affect performance by balancing efficiency and noise levels. Mechanical efficiency exceeds 95% in modern turboprop engine designs. Gas turbine engine compresses air, mixes it with fuel, combusts it, and expands gases through turbine stages. Exhaust thrust contributes to propulsion in turbine engines but minimally in turboprops. Turboshaft engines resemble turboprops by driving a shaft connected to rotors or machinery instead of a propeller. Gearbox systems achieve efficiency rates exceeding 95%, guaranteeing minimal energy loss during torque transfer. Aircraft propulsion systems in turbine engines utilize direct propulsion via exhaust thrust. Turboprop work involves converting high-speed turbine rotation into efficient propeller operation through gearbox power conversion. Turboprop use emphasizes driving a propeller for thrust instead of relying on jet propulsion.

What is the difference between a turboprop and a jet?

Parameter | Turboprop | Jet |

Thrust Mechanism | Gas turbine engine drives a propeller via a gearbox | Exhaust gases from combustion expelled through rear nozzle |

Speed Range (knots) | 200–400 knots (108.52–217.04 km/h) | Exceeds 600 knots (1111.2 km/h) |

Optimal Altitude | Below 30,000 feet (9,144 meters) | Above 40,000 feet (12,192 meters) |

Fuel Efficiency | Higher fuel efficiency for short-haul and low-altitude | Lower fuel efficiency due to high-speed performance |

Design Configuration | High-wing design with T-tail to avoid propeller downwash | Low-wing design for stability at high speeds |

Engine Placement | Engine integrated with propeller system | Engines mounted on wings or rear fuselage |

Mission Suitability | Short-haul regional flights, lower operating costs | Long-haul, high-speed, high-altitude missions |

Propulsion Focus | Mechanical thrust via propeller rotation | Direct thrust via exhaust gas acceleration |

What is the difference between a turboprop and a turbojet?

Feature | Turboprop Engine | Turbojet Engine |

Thrust Mechanism | Propeller driven by power turbine via gearbox | High-velocity exhaust gases through nozzle |

Maximum Efficiency Speed | Below 500 km/h (310.7 mph) | Above 900 km/h (559.2 mph) |

Optimal Altitude | Under 30,000 feet (9,144 meters) | Above 35,000 feet (10,668 meters) |

Exhaust Velocity | Not applicable (propeller-driven thrust) | Exceeding 1,000 m/s (3,280.84 ft/s) (1,093.61 yd/s) (0.621371 mi/s) |

Energy Conversion | Over 80% of gas turbine energy to usable thrust | Energy fully converted to exhaust velocity |

Propeller Integration | Includes propeller with adjustable pitch | No propeller |

Propeller RPM Range | 1,500–2,000 RPM (via gearbox) | Not applicable |

Propeller Diameter | Exceeds 2 meters (6.56 feet) | Not applicable |

Gearbox Requirement | Yes (to reduce turbine speed for propeller) | No |

Fuel Efficiency | High at speeds below 500 km/h (310.7 mph) | Lower; optimized for high-speed performance |

System Complexity | Includes gas turbine, gearbox, and propeller | Simplified: compressor, combustion chamber, turbine |

Primary Use Case | Regional flights, cargo transport, lower altitudes | Long-distance travel, high-speed, high-altitude |

Turbojet engine direct thrust relies on high-velocity exhaust gases expelled through a precisely designed nozzle. Exhaust system nozzle design accelerates gases to velocities exceeding 1,000 m/s (3,280 ft/s), generating forward thrust. Exhaust velocity directly contributes to the aircraft's propulsion system thrust production. The engine configuration excludes a gearbox or propeller, simplifying its structure but limiting efficiency at lower speeds. Turboprop engines convert turbine energy into mechanical thrust via the propeller, driven by the power turbine through the gearbox. Turbojet engines rely solely on exhaust velocity for thrust, with no propeller integration. Thrust production in turboprops depends on the propeller's rotational motion, while turbojets expel hot gases directly. Aircraft propulsion system system configuration in turboprops includes a gas turbine, gearbox, and propeller, whereas turbojets consist only of a compressor, combustion chamber, turbine, and nozzle. Trade-offs in aircraft propulsion system fuel efficiency arise from the need for high exhaust velocity in turbojets versus the propeller-driven efficiency of turboprops. Turboprops consume less fuel at speeds below 500 km/h (310.7 miles/h), while turbojets demonstrate higher consumption but achieve faster speeds exceeding 900 km/h (559.2 miles/h).

What is the difference between a turboprop engine and a turboshaft?

Differences between a turboprop engine and a turboshaft are explained in the table below.

Aspect | Turboprop Engine | Turboshaft Engine |

Primary Function | Generates thrust through a propeller | Produces shaft power to drive rotors or machinery |

Application | Fixed-wing aircraft propulsion | Helicopter rotor systems and industrial machinery |

Thrust Mechanism | Over 80% of thrust comes from the propeller | Shaft power is converted into high-torque motion |

Efficiency | Better fuel efficiency below 450 mph (724 km/h) | Optimized for high-torque applications in helicopters |

Propeller/Rotor Drive | Propeller integration with aerodynamic blade design | Gearbox coupling converts turbine output to rotor motion |

Gearbox Role | Adjusts propeller speed for aerodynamic performance | Converts high-speed, low-torque to low-speed, high-torque |

**Key Advantage | Fuel-efficient regional and short-haul flights | Enables vertical lift and precise maneuverability |

Typical Use Case | Regional flights, fixed-wing aircraft | Helicopters, industrial equipment |

What are the advantages of a compact turboprop engine?

The advantages of a compact turboprop engine are outlined below.

- Compact turboprop engine’s efficient packaging optimizes space within the aircraft, reducing structural weight, drag, and elevating aerodynamics and overall aircraft efficiency.

- High power-to-weight ratio of compact turboprop engines enhances takeoff and landing performance, especially on shorter runways measuring as short as 3,200 feet (975 meters).

- Compact turboprop engine’s reduced weight decreases fuel consumption, with turboprops burning up to 40% less fuel compared to jet engines (two-thirds of the fuel per passenger).

- Lower fuel burn rates in compact turboprop engines translate to cost savings, making them ideal for regional and short-haul flights under 500 nautical miles.

- Compact turboprop engine weight reduction enhances payload capacity without compromising performance, allowing more cargo or passengers.

- Compact turboprop engine’s versatile installation adapts to both small commuter planes and larger regional aircraft, aiding diverse operational needs.

- Reduced emissions in compact turboprop engines aligns with environmental compliance standards, lowering carbon emissions for eco-friendly operations.

- Compact turboprop engine’s noise reduction benefits noise-sensitive areas, decreasing disturbance during operations near urban or sensitive environments.

- Compact turboprop engine’s cost efficiency reduces operational costs, benefiting stakeholders through lower fuel consumption and maintenance needs.

- Ease of access for repairs of compact turboprop engines decreases downtime, allowing quicker returns to service and extended aircraft service periods.

- Compact turboprop engine’s reliable operation ensures consistent performance for flights below 25,000 feet (7620 meters), ideal for remote or underserved regions.

- Compact turboprop engine’s affordability in lifecycle makes it a preferred choice for operators focusing on short to medium-range missions.

- Compact turboprop engine’s versatility supports military applications and regional airlines needing reliability for specific mission profiles.

What is the efficiency of a turboprop engine?

The efficiency of a turboprop engine depends on factors like propulsive efficiency at speeds up to Mach 0.5 to 0.6, overall efficiency for typical aircraft, and optimal low-altitude and low-speed conditions. Turboprop engines achieve propulsive efficiency of 50% at speeds up to Mach 0.5 to 0.6. Overall efficiency for typical aircraft operations ranges from 20% to 40%. Under optimal low-altitude and low-speed conditions below 725 km/h (450 mph), turboprop engines reach efficiencies around 30%. Exergy efficiency measurements for turboprop engines report values between 76% and 77%. Dynamic flight conditions cause efficiency variations, with reductions ranging from 15% to 25.9%.

How fast do prop planes fly?

Prop planes fly at speeds ranging from 80 (129 km) to 413 (664 km) mph, depending on their design and purpose. Small single-propeller planes cruise at speeds of 125 knots (144 mph or 232 km/h). Turboprop engines optimize performance within the speed range of 250 to 400 mph (402-644 km/h). The Spitfire PR.XIX achieves speeds of up to 690 mph (1110.4 km/h) during emergency dives, marking it as an exceptional case for propeller-driven aircraft. Commercial airplanes operate at speeds averaging 800 to 900 km/h (497-559 mph), contrasting with prop planes. Certain prop planes have a maximum speed limit of 185 m/s (413 mph), depending on design and conditions.

Smaller propeller models operate within a speed range of 80 to 120 mph (129-193 km/h), catering to recreational and training purposes. Single-engined prop planes cruise at speeds ranging from 100 to 120 knots (185-222 km/h), reflecting their utility in general aviation. Fast single-engine propeller aircraft achieve speeds around 217 knots (402 km/h), marking the threshold for high-performance piston-driven designs. The Wright brothers' Flyer achieved a speed of about 30 mph (48 km/h), during its historical first flight, illustrating the early limitations of powered flight. Certain variants of the Spitfire achieve speeds exceeding 600 mph (965 km/h) during dives, showcasing exceptional performance under extreme conditions.

Turboprop engines optimize performance within the speed range of 250 to 400 mph (402-644 km/h) making them ideal for regional and cargo operations. The Beechcraft King Air 350 cruises at speeds up to 320 ktas (368 mph), while the ATR 72 operates at speeds up to 270 ktas (310 mph),. Prop planes demonstrate a wide range of speeds, from small recreational models to high-performance aircraft, each optimized for specific use cases. Some propeller aircraft have maximum speeds limited to 185 m/s (414 mph) due to design constraints.

How far can a prop plane fly?

The distance a prop plane can fly depends on factors like fuel load, passenger and luggage payload, weather conditions, and specific aircraft design. Minimal fuel and full passenger load limit the range to 400 nautical miles. Standard cruising with moderate luggage and two passengers extends the range to 720 nautical miles. Optimized fuel load, lightweight luggage, and one passenger increase the range to 900 nautical miles. Long-range flights with minimal luggage and favorable weather conditions reach up to 1,000 nautical miles. Specialized aircraft with extra fuel tanks achieve a range of 1,700 nautical miles under ideal conditions.

Turbocharged or turboprop aircraft demonstrate superior performance capabilities under optimal conditions. These advanced prop planes achieve ranges up to 2,500 nautical miles by leveraging increased power and efficiency. The integration of variable-pitch propellers and aerodynamic enhancements further maximizes their operational potential. Favorable weather reduces drag, while reduced payload allows for greater fuel capacity, contributing to extended flight distances. Propeller efficiency and engine optimization play are vital in achieving these ranges.

Are turboprop planes safe?

Turboprop planes' safety depends on operational practices, maintenance procedures, and compliance with stringent safety standards. Turboprop planes exhibit a fatal accident rate of 0.55 per 100,000 flight hours compared to jets at 0.09 per 100,000 flight hours. Pilot training ensures proficiency in handling weather conditions and instrument flight rules, directly impacting safety outcomes. Regular maintenance schedules identify potential issues before they become dangerous, guaranteeing structural integrity and engine reliability. Emergency protocols for engine failures and severe weather reduce risks during incidents. Safety standards enforced by regulatory authorities like the FAA and EASA guarantee compliance through rigorous certification processes.

Regulatory authorities like the FAA and EASA assess the safety of turboprop planes through rigorous certification processes and continuous compliance enforcement. These evaluations assure safety for passengers, pilots, and crew while addressing differences between private owners and commercial operators. Private operators face less stringent operational oversight compared to commercial entities, which adhere to stricter aviation safety standards. Comparative aircraft design risk assessment highlights unique risks and advantages of turboprops and their performance in lower-altitude environments. Accident statistics show that turboprops account for 50% of all aviation accidents and 86% of fatal accidents, emphasizing the need for robust safety measures.

Design compliance to safety standards ensures that turboprop planes meet structural integrity and engine reliability requirements. Turboprop planes exhibit an accident rate of 1.54 per 100,000 flight hours, with a fatal accident rate of 0.55 per 100,000 flight hours. Maintenance and inspection schedules are vital to maintaining airworthiness and preventing mechanical failures. Regular inspections focus on engine performance, propeller systems, and landing gear to identify potential issues before they become dangerous. Pilot training emphasizes proficiency in adverse weather conditions and instrument flight rules, directly impacting turboprop planes flight safety.

Comparative aircraft design safety features reveal that turboprops operate efficiently at lower altitudes but face increased exposure to weather hazards. Jets experience 0.51 accidents per 100,000 flight hours, reflecting their superior safety record. Aviation safety risk mitigation strategies include identifying hazards like severe weather or mechanical issues and implementing measures to minimize risks. Preventative maintenance plays a vital part in guaranteeing turboprop plane engine reliability and overall flight performance.

Operational practices and emergency protocols address pivotal phases of flight, including takeoff, cruising, landing, and emergencies. Lower service ceilings in turboprop aircraft increase the need for instrument flying, making pilot training pivotal for safe operations. Safety testing protocols validate the performance of turboprop designs before service entry. Regulatory certification processes guarantee ongoing compliance with maintenance and inspection requirements. Accident statistics and failure analysis aids in understanding causes of incidents and elevating safety measures. Turboprop planes operate efficiently in specific environments, offering advantages in fuel efficiency and handling capabilities despite inherent risks.

What is the size of prop planes?

The size of prop planes is given in the table below.

Aircraft Type | Propeller Size Range (Diameter) | Additional Specifications |

General Aviation | 1.4–1.8 m (4.6–5.9 ft) | Common sizes: 10x6 (25.4 x 15.2 cm), 8x 6 (20.3 x 15.2 cm) Speed range: 200–300 mph (321.87–482.80 km/h) Range: 500–1,500 miles (804.67–2,414.02 km) |

Cargo Planes | Up to 2750 mm (108.27 inches) | Enables payload capacity and extended ranges Operational range: >2000 km (>1242.74 miles) |

Drones | 5.1 x 3.8 x 3 (diameter x pitch x blades) | Reflects unique thrust requirements |

Light General Aviation | 4.6–6.0 ft (1.4–1.8 m) | Detailed measurements: 10 x 4-7 (diameter x hub pitch x tip pitch) |

A minimum clearance of 9 inches (22.86 centimeters) is maintained when the tail is level to prevent propeller strikes during takeoff, landing, or taxiing. This clearance requirement applies to both general aviation and larger turboprop aircraft, safeguarding against potential damage to the propeller or airframe. Safe ground clearance ensures the propeller operates efficiently without interference from uneven surfaces or obstacles.

What is a turboprop biplane?

A turboprop biplane is an aircraft that combines the efficient thrust generation of a turboprop engine with the high-lift characteristics of a dual-wing configuration, offering potential advantages in specialized flight scenarios. Turboprop engines drive a propeller through a reduction gearbox, converting mechanical energy into thrust. Biplanes feature two main wings stacked one above the other, creating visible structural interference but elevating lift at low speeds. The combination of turboprop efficiency and biplane lift offers unique advantages in specialized flight scenarios like agricultural spraying or short takeoff and landing operations. Turboprop biplanes generate thrust through the propeller, with additional force derived from exhaust gases produced during combustion. Modern aviation rarely employs turboprop biplanes due to their reduced efficiency compared to monoplane designs.

The biplane's dual-wing arrangement features two main wings stacked vertically, with the lower wing attached to the fuselage and the upper wing aided by cabane struts. This wing configuration enhances lift generation at low speeds, making it advantageous for short takeoff and landing operations. Structural interference between the wings reduces aerodynamic efficiency, but robust bracing and additional struts maintain stability and prevent flexing. The dual wings contribute to stability and control during low-speed maneuvers, a vital factor in specialized flight scenarios.

Incorporating a turboprop engine into the biplane airframe requires precise alignment of the engine’s thrust vector with the aircraft’s center of gravity. Aircraft structural design supports the stresses imposed by both the engine and the braced wing structure, guaranteeing compatibility with cooling and fuel systems. The aerodynamics of a turboprop biplane benefit from the dual-wing configuration, which maximizes lift while accommodating the added weight of the engine. Interaction between the propeller wash and the biplane wings demands careful analysis to optimize lift and drag characteristics. Aircraft aerodynamics play a pivotal part in determining how effectively the design harnesses its components for better performance.

Turboprop biplanes excel in niche aviation scenarios like agricultural spraying or short-field operations. The combination of turboprop engine efficiency and biplane lift offers unique advantages in these missions, despite reduced aerodynamic efficiency compared to monoplanes. Historical use cases include crop-dusting operations, where the design's stability and maneuverability at low speeds were vital. Modern applications leverage the turboprop biplane’s hybrid design for tasks requiring high efficiency at low altitudes and speeds, demonstrating its continued relevance in specialized aviation needs.

What is the price of a prop plane?

The price of a prop plane depends on factors like age, condition, and model. New ultralight aircraft start at $8,000 USD, while used ultralight models in good condition cost around $15,000 USD. Older single-engine piston planes requiring minor repairs cost $30,000 USD, whereas those in excellent condition reach up to $300,000 USD. High-Time Cherokee Six aircraft with no immediate overhaul requirement are priced at $100,000 USD. New single-engine piston planes with modern features, like the Cirrus SR20, range between $230,000 and $430,000 USD.

Mid-range options include high-time Cherokee Six aircraft with no immediate overhaul requirement priced at $100,000. Used single-engine planes in excellent condition reach up to $300,000, appealing to buyers seeking reliability and performance. Modern single-engine piston planes like the Cirrus SR20 range between $230,000 and $430,000, offering advanced avionics and refined safety features. New small single-engine turboprop aircraft start at $2,205,000, targeting operators needing greater efficiency and payload capacity. High-end large twin-engine turboprop aircraft with advanced avionics are priced at $8,810,000, serving industries requiring long-range capabilities and robust performance. Single engine planes dominate the market for private ownership due to their balance of affordability and functionality. Prop plane cost varies based on factors like age, condition, and equipment, with single-engine piston models representing the most accessible entry point. Prop plane price for private owners centers on the $30,000 to $300,000 range, encompassing older single-engine planes needing minor repairs and those in excellent condition.